The importance of QC in a global economy

The feed sector must focus on quality, safety and efficacy if we are to meet the needs of future generations in an ethical and sustainable manner. Strong company quality systems coupled with harmonised regulatory agencies are needed to protect and promote new technologies such as functional foods, nutrigenomics and nanotechnology, while at the same time provide a secure system that protects our technology.

By Matthew Russell, European Quality Assurance Manager, Alltech European Bioscience Centre, Co. Meath, Ireland

A growing global population, better living standards and an expanding middle class in countries such as China and India, and the increasing global demand for food and feed, requires specific need for increased milk and meat production in these countries. Better animal husbandry will deliver much of the produce required but with our help this can be done more efficiently using new technologies to deliver precision feeding and better feed conversion.

These areas of research are already beginning to influence the way companies are working and building for the future. Regulators are also starting to recognise the advantages of these new technologies such as the benefits of using organic selenium. The challenge for companies operating in this market is to deliver these very advanced technological products in a fully traceable and safe manner while protecting commercially sensitive information. This must also be done in a way that respects local regulations and ensures that we provide a product that is nutritional, ethical and sustainable.

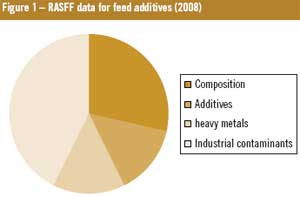

There is no doubt that the feed sector has been damaged by a number of safety issues. In response, the companies involved, trade associations and regulatory bodies have made enormous efforts to reduce these incidents as much as possible. One of the most important aspects of this has been cooperation between different regulatory bodies across the world to share information and spread awareness of emerging risks in their local market with other stakeholders. A good example of this cooperation is the EU’s Rapid Alert System for Food and Feed (RASFF, See alert results in Figures 1-3), which immediately communicates any identified risks to the feed and food chain as they happen. This now forms part of a global notification system with the World Health Organisations (WHO) and International Food Safety Authorities Network (INFOSAN) allowing for the rapid distribution of information between regulatory bodies at a global level. This is a great benefit to the consumer and regulators but also means that consumer trust in a brand can be wiped out in a matter of hours. Rather than fear these developments however, we should embrace them with a view to eliminating those companies who will not raise their standards. The rising tide of quality assured product will lift the sector as a whole.

Traceability pillar

The single most important pillar of a safe feed sector is traceability. This has come to be known as the “one step up, one step down” approach and is used throughout the industry. It is now clear that the longer you can make this chain the stronger your traceability and as a result companies such as Alltech try to cooperate with as many different steps of the feed chain as possible, an initiative which is now being encouraged by regulators. Many tools are available that allow a large amount of data to be stored on batch identification tags such as data matrix and databar bar codes. RFIDs (Radio Frequency Identification) and the Transatlantic Traceability Infrastructure (TTI) project provide platforms to develop this process further.The weakness of the “one step up, one step down” approach was illustrated during the 2008 pork dioxin crisis in Ireland. Although the pork industry had the regulated level of traceability in place, due to the logistical difficulties involved in quickly collecting the relevant data, the Irish Department of Agriculture had no alternative but to initiate a full recall of all Irish pork products for three months despite only a small proportion actually being contaminated. A more easily accessible traceability system might well have eliminated the need to initiate a recall that affected up to 54 countries. To their credit, the prompt action of the processors, the Irish Government and the RASFF meant that they were still able to exert sufficient control over a potentially very serious contamination issue.

HACCP implementation

The above example might never have been an issue if a full Hazard Analysis and Critical Control Point (HACCP) system had been effectively implemented for the feed producer involved but a formal investigation is ongoing in this regard. A legal requirement for all feed produces in the EU, HACCP is fast becoming the industrial standard in the global feed sector. This is the principle of a risk based approach to product safety, where all elements of a material and its associated processes are examined with the end user in mind. It is therefore necessary for all steps of the feed chain to be fully aware of the application of their products further down stream.

Regardless of whether a formal HACCP system is used, the focus on a product’s safety for those using it down stream, still remains paramount to protect the user and the brand.

Chemicals misuse

A detailed risk analysis can sometimes also highlight ways in which chemicals in particular, are misused in the feed sector. These instances can be a result of adulteration such as melamine but they can also be caused by upstream processing, where the operator is unaware of the effect a given chemical could have on the finished feed. An example of this was seen when inactive yeast was exported from South America with traces of Monensin present. The producers had not acted incorrectly when using Monensin in their distillation processes but a hazard analysis would have shown the problems this could cause the feed sector, where the inactive yeast was being sold as a co-product. Further to this, the purchasers’ own HACCP system should have highlighted the risk of antibiotic contamination in this yeast and tested the imported material accordingly. Once highlighted however, the EU Commission was quick to evaluate the risk and set a safe limit for Monensin in feed that quickly eliminated any confusion in the EU or South American market.

One central standard

The examples above illustrate how local issues can quickly become serious global problems that can affect hundreds of tonnes of feed or food in dozens of countries. The regulations that currently exist in the feed sector are very important but should be considered the minimum applicable standard. While regulations are imposed retrospectively, a strong and proactive quality system focused on identifying and controlling threats will highlight problems before they have the potential to compromise operations. There are currently many local and regional regulations to consider along with a wide variety of quality systems. While these need to be harmonised to avoid unnecessary duplication and to close gaps in the sector, they will always be generic and as such must be integrated into an organisation to make them specific to different products and processes.

To deal with these variations, Alltech conducted a review of the different regulations and quality systems applied globally throughout the company and around the world. This led to the creation of the Alltech Quality System (AQS) which takes the best from these regulations and systems and forms one quality standard that must be applied to all Alltech production sites, regardless of their location. The AQS system, though strict, must still be refined further on each site to apply complete traceability and HACCP principles to every product related process.

In this way, all Alltech sites meet the same high quality standards but the details of the AQS will differ depending on the production processes in use. For example, in line with HACCP evaluation and recent market notifications, Alltech has implemented a 100% testing programme for dioxins, PCBs and heavy metals called the ‘Q+ system’. This analysis is specifically conducted on the Bioplex range of organic trace minerals and is a demonstration to customers of the confidence they can have in an Alltech product. The Q+ initiative is just one example of the sort of control that a detailed HACCP programme can deliver to our sector.

Consumer confidence

Raw material costs also pose a major concern in the global feed market as we build for 2050 and beyond with increased competition for land and cereal resources. There are now technologies available to help better feed conversion and hopefully this will help alleviate some of the pressure on these materials. However, this would need to occur in addition to the removal of trade barriers that are preventing safe and legally approved raw materials entering the market. This continues to be an issue in the EU and now Turkey has reacted to severe public pressure by implementing a GMO testing programme to control a problem that may have no safety value in their market. This is a clear example of where a lack of consumer confidence results in poor regulation that does little to support the food and feed sectors.With this in mind it is clear the feed sector must focus on quality, safety and efficacy if we are to meet the needs of future generations in an ethical and sustainable manner. Strong company quality systems coupled with harmonised regulatory agencies are needed to protect and promote new technologies such as functional foods, nutrigenomics and nanotechnology, while at the same time provide a secure system that protects our technology.

Traceability and prompt communication across the sector will allow us to better deliver the most technologically advanced feed ingredients, help farmers to meet the world’s growing dietary needs, and assist more countries in raising their standards of living, health and immunity.

Source: AllAboutFeed vol 1 nr 2, 2010

Join 26,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the feed sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht