Understanding phytase characteristics to differentiate products

Phytase enzymes currently available commercially differ markedly in terms of their characteristics, which makes direct comparisons extremely difficult. The recent launch of several new products onto the market has only added to this variety, and increased the challenge faced by end users needing to differentiate between the products on offer.

Dr Mike Bedford, Research Director AB Vista Feed Ingredients

Whilst the main differences in phosphorus (P) release at standard phytase dose rates are accounted for in the published nutrient matrices for each phytase, such information is much less relevant at higher dose rates or when superdosing to eliminate phytate as an anti-nutrient. Most end users also still rely heavily on animal trials to help differentiate between products, with those trials often conducted under less than ideal conditions, resulting in potential errors that can negatively affect subsequent product-buying decisions.

What’s needed is a fresh approach to phytase comparison, and it appears that a greater understanding of the various characteristics of each phytase – and their interactions – may be the key. This was backed up by several presentations at the Second International Phytase Summit, held in Rome last December, which highlighted the importance of a number of phytase characteristics when assessing potential performance.

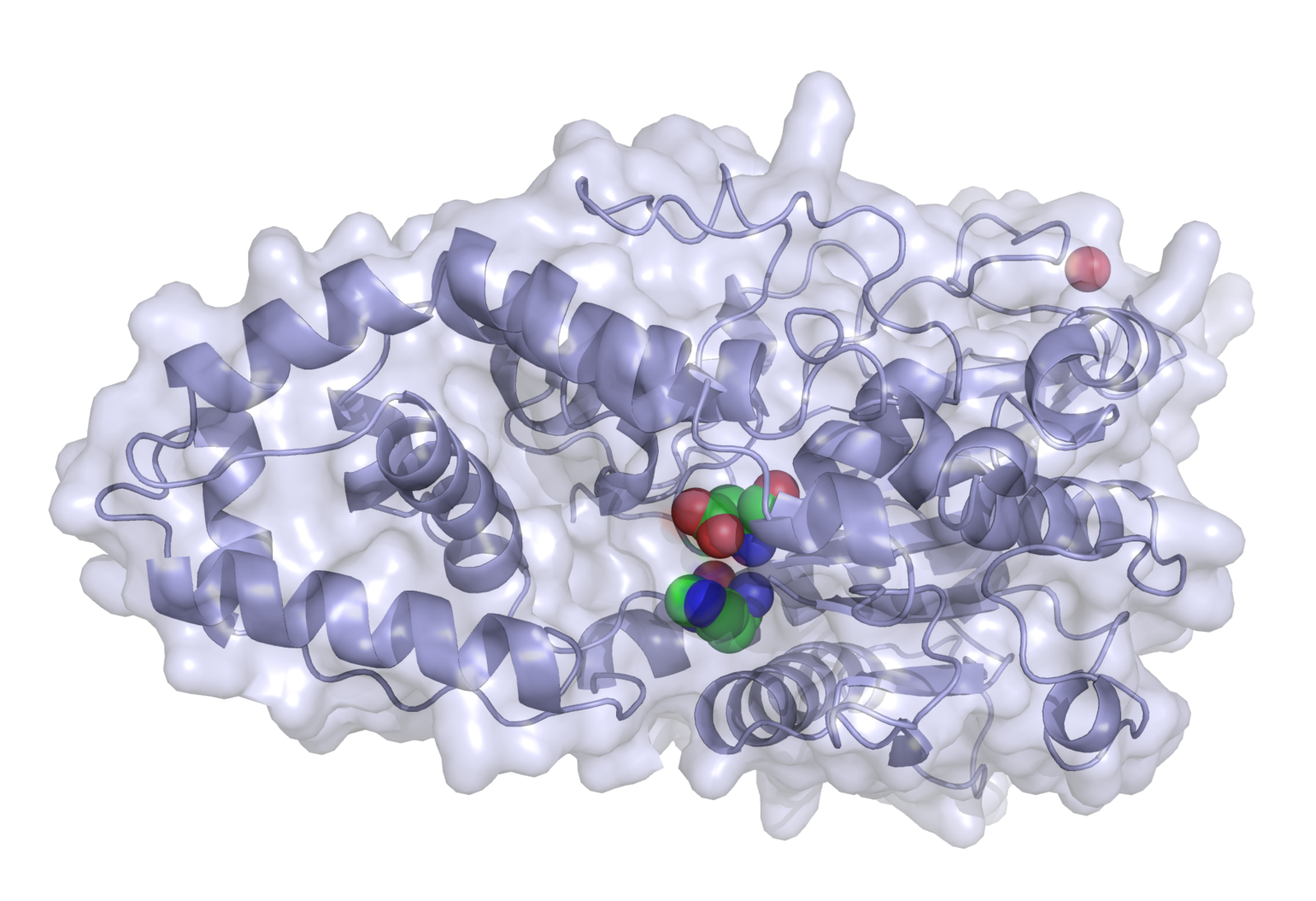

Relative to commercial fungal phytases traditionally sourced from P. lycii and A. niger, for example, products which are E. coli-derived are generally more thermostable, more acid stable and more protease resistant. They are also more active at the acidic pH typically found where phytases act in the animal gut (Figure 1).

What’s more, these characteristics have been further enhanced in 2nd and 3rd generation E. coli phytases. Consider that the development of current 3rd generation enhanced E. coli phytases has raised the ‘melting point’ – a simple laboratory measure used to determine the temperature at which an enzyme starts to denature – from 60oC to 89oC. That’s a significant improvement in thermostability.

Such characteristics are potentially important for a number of reasons, and increasingly so when higher levels of phytate destruction are required. Greater thermostability is a good example, and can make it unnecessary to use coating technologies which may delay the release of a phytase in the stomach or gizzard. With any such delay capable of reducing efficacy, particularly at superdosing levels (when every additional second available for phytate destruction is of value), such characteristics become critical when evaluating and comparing the performance potential of different phytases.

There are also differences in how phytases behave within the gastrointestinal tract. Phytate is easily degraded in the acidic environment of the stomach or gizzard, so the activity of phytase enzymes within the range pH2-4 is another useful measure of efficacy (Figure 2).

However, perhaps the most important characteristic to emerge as an influence on performance in recent years is the Km of a phytase, which is defined as the concentration of phytate required for the enzyme to operate at 50% of its maximum capacity. A lower Km means that the phytase is capable of working at lower concentrations of phytate in the diet, and this has several extremely important implications.

The first is that a commercial phytase product with a lower Km will act sooner when concentrations of available phytate in the stomach rise following a meal, and will continue acting for longer as phytate is broken down by the phytase and concentrations eventually begin to drop. Figure 3 compares the activity of two example phytases, with the 3rd generation E. coli product (Km=5µm) clearly much more active at low phytate concentrations than a 1st generation product (Km=150µm).

At the standard level of dosing to release 50-60% of the P locked up in dietary phytate, equivalent to an increase in available P (avP) of 0.10-0.13%, these differences are generally unimportant. However, as demand for a greater extent of phytate breakdown has grown – up to 70-75% to release 0.15-0.17% avP to further reduce feed costs, and as high as 80-85% when superdosing to eliminate negative effects of phytate on nutrient digestion – so too has the importance of Km.

In fact, given that some phytate is insoluble (unavailable), such high levels of phytate breakdown may require available stomach phytate concentrations to be reduced to 0.05% or below. For the commercial phytase products with higher Km values, this may not be possible – activity would simply cease before concentrations get this low.

The other implication revolves around superdosing, and the ability of a phytase to effectively ‘neutralise’ phytate as it becomes available, but before it reaches a concentration at which it has negative effects on the digestion of other nutrients. Regardless of whether this increase in soluble phytate is due to ingestion of feed, or the result of more insoluble phytate being released as the level of soluble phytate in the stomach drops, the impact is the same.

Figure 4 shows the increase in available phytate in the stomach over time for diets dosed with two different phytases (one high Km, one low Km). If the point at which negative effects on digestion appear is 0.6 on the graph (red line), then a phytase able to start acting sooner (low Km) and which can reach a rate of activity that matches the rate of phytate release below 0.6 will be highly effective – that critical phytate concentration will simply not be reached.

For the high Km product, which needs a much greater phytate concentration to achieve the same rate of activity, the balance between phytate release and degradation may be too high to prevent the negative effects of phytate on nutrient availability, regardless of how high a phytase dose rate is applied.

The conclusion is that not all phytases capable of delivering 0.10% avP are suitable for achieving higher levels of avP release, and that even fewer are capable of providing superdosing benefits through complete phytate destruction. Put simply, the ability of a phytase to rapidly attack phytate as it dissolves, and continue the attack until very little phytate is left, is essential to the removal of phytate as an anti-nutrient.

Understanding such characteristics is vital when trying to differentiate between commercial phytases, particularly when looking to use higher dose rates or gain full advantage from potential superdosing benefits. Similarly, the need to publish data on phytase characteristics such as thermostability, pH profile and Km values will increase as new phytases are introduced, and performance boundaries are extended.

For the end user, that ongoing evolution of phytases should mean better choice, more effective products and a greater return on investment. However, such commercial success will remain dependant on being able to effectively and accurately compare products on the basis of properties that directly affect animal performance.

Dr Mike Bedford

Dr Bedford oversees the development of enzyme and yeast products for use in ruminant and non-ruminant feeds. He has experience in the feed additives industry through working in different research and development teams.

Having gained his PhD in Poultry nutrition and biochemistry at the University of Guelph in Canada, he undertook two post doctorate posts in Canada in Molecular Biology and Poultry Nutrition. Since then, Mike has written or been involved with over 200 publications including 76 refereed full scientific papers, and 92 abstracts of material presented at conferences.

Join 26,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the feed sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht