A closer look at feed structure

In pig farming animal health and particularly the health of the gastrointestinal tract (GI-tract) is a major subject for research. “Preventing dysbioses through the best possible support to the GI-tract eubiosis” is the challenge that we must face in all feeding measures. Feed additives are often used in this challenge. But having a better grip on the structure of the feed is an underestimated and cheap tool to aid gut health.

The influence of different additives on the intestinal health has been extensively studied in recent years in practical feed research. The issue of diet formulation in different studies was also taken into account. However, also the technical behaviour of the feed in the GI-tract plays a central role in promoting gut health. This is where feed structure is of special importance. The raw materials for a compound feed can be individually milled before mixing or together after mixing. This gives the mash feed mixture a characteristic structure depending on the grinding techniques (e.g. hammer mill vs. roller mill), the sieve used in the hammermill, the distance between the screen and hammers and of course the raw materials used. As such, wheat is ground finer than barley when using identical technical equipment. In addition, other raw materials in the mix such as corn, soybean meal, rapeseed meal, wheat bran, beet pulp, etc. have specific milling properties. It raises the question of how the structure of a feed mixture with objectively measurable criteria can be assessed.

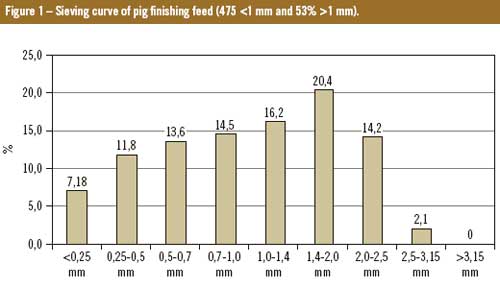

The easiest way is to determine the particle size distribution with a fraction sieve. In Figure 1, the sieve analysis of a commercial mash feed (13.0 MJ ME per kg, 17% crude protein, 0.9% lysine) is shown, with grain, grain by-products, soybean meal and rapeseed meal as basic compounds. This structure from a practical point of view can be classified as “well structured” and “perfect”.The answer to the frequently asked question about the right choice of screen perforations in the classic hammer mills depends on the used mill technology (type of screen, hammer speed) in the feed plant or on the farm. In both situations, the technical quality of screen and hammers should be checked regularly. According to studies by Lindenmaer (2008) screen perforation size plays a minor role compared to the quality of the hammers in achieving a good grind. Worn hammers produce more fine meal with a high proportion of dust – even on coarse sieve sizes.

Particle size in pellets

Feed for sows, piglets and fattening pigs in many cases is not fed as mash but is technically agglomerated into pellets or granules (pellets coarsely ground on a roller mill). The reasons for this are many: improved flow characteristics in feed silos and feeders, less segregation during transport in the feeding systems, minimised feed losses in feeders, reduction of dust in the barn and a positive influence on feed intake and feed conversion.

Particle size of ingredients in granuled or pelleted feed is smaller in mash feed with the same components. Due to the pelleting process itself, in which the feed is pressed through die holes of 3 to 5 mm diameter, another technical unavoidable crush is taking place. These from the viewpoint of animal nutrition distinguishing features of pelleted (or granulated) and well-structured mash feeds are summarised in Figure 2.

Determination of particle size distribution in a mash feed is quite easy using a dry sieve method. Much more complex, however, is the determination of particle distribution in a pelleted or granulated feed. Visscher (2006), Offenberg (2007) and Great Liesner (2008) have described the so-called “wet sieve analysis for pelleted compound feed”, which has been modified for our company’s own tests to obtain the fractions >1 mm and <2 mm, and identify >2 mm and the resulting sum for >1mm. First, it should be noted that dissolving the feeds in water already leads to a change in particle size distribution due to swelling and dissociation processes. In our own test a direct decrease in the particle size fraction of >1 mm by 5-7% could be determined.

For further research therefore we omitted wet sieving of mash feed before pelleting. The values of the dry sieved mash were used in the test series. In Figure 3 and 4 results are presented of different particle size fractions before and after pelleting of grower feed (3.3 mm die) and sow feed (4.7 mm die and granule on roller mill). Feed structure was changed by the pelleting process. The share of particles >1 mm was almost reduced by 50%, compared to the pre-press mash. Extensive further in-house research – including also broiler feed – showed that particle size distribution of the press meal has a decisive influence on the particle size distribution in the pellet or granule. It also became clear that using a press meal with an even coarser structure – in the test, a broiler feed with 62% of particles >1 mm in the press meal – does not result in a higher proportion of particles >1 mm in the pellet with the currently used techniques. Rather, in poor technical settings (e.g. larger distance between roller and die in the press) loss of structure tend to be maximised (only about 10% of particles >1 mm in the pellet compared with about 25% for optimised procedure). Based on these data in ongoing projects further technical possibilities will be studied to minimise the loss of structure in pelleting of feeds.

Recommendations

a) The feed structure of mash feed or pelleted or granulated feed for pigs can be produced according to current scientific and practical knowledge using the following parameters and assessments:Mash feed: at least 40 to 45% of particles >1 mm (dry sieve method for meal);b) Press meal for the production of pellets or granules for sows, piglets and fattener feed: at least 50% of particles >1 mm (dry sieve method for meal). It should be noted that with the wet sieve analysis (due to the dissolving process) already at least 5 percentage points are lost for particles >1 mm compared to the dry sieve analysis.c) During pelleting a technical unavoidable crushing is taking place. The level of this unavoidable crush can be optimised by technical and physical means. Based on this it is required for pelleted or granulated pig feed to have a “feed structure in the agglomerated product” of at least 20% particles >1 mm (determined by wet sieving of the pellets or granules).It is expected that future technical developments in feed compounding will further solve the problem of technically unavoidable crushing during pelleting.