Preconditioning for extrusion of aquafeed – Part 2

Preconditioning, as applied in the manufacture of feed, involves adding moisture and heat to the feed formulation before extrusion (or pelletising). In the second part of this article, we explain the key parameters and the different types of preconditioners.

In Part 1, we explained what preconditioning is and what its benefits are. But what are the key preconditioner operating parameters? For the cooking reactions to occur within the formulation, two key parameters need to be controlled and optimised – these are providing a sufficient amount of water and an elevated temperature. Injection of live steam into the preconditioner provides both heat and moisture simultaneously. The effectiveness of the steam in achieving the objectives depends on 2 mechanisms. These are:

- The internal resistance: this relates to the mass diffusion (for hydration) and thermal diffusion (for heating) properties of the material being processed. The composition of the material and the particle size distribution of the feed both have a strong influence; and

- The film resistance: this relates to the external resistance to mass transfer and/or heat transfer to the material being processed. The type and uniformity of the mixing within the system have the greatest influence on this characteristic. For most feed materials, the rate of heat transfer (measured via thermal diffusivity) is much faster (typically around 100 times faster) than the rate of mass transfer (measured via mass diffusivity). As a result, the preconditioning process is described as a mass diffusion-controlled process – the particles heat relatively easily, so the operation limits tend to be determined by the need for hydration/wetting.

Critical points for mass transfer and heating

So for a chosen formulation, we should maximise the mass transfer (hydration) capability of the system. The following points should be considered:

- To the extent possible, ensure particles are small and have a uniform particle size distribution (the mean particle diameter and the standard deviation should both be as small as possible)

- Ensure there is intimate contact between the steam and the particles (ensure a good mixing action)

- Ensure adequate residence time in the preconditioner, with narrow residence time distribution (see the following for discussion of these aspects).

While heating may be considered “easier” to achieve, it is nonetheless critical. To ensure heating is carried out effectively and efficiently:

- Ensure the quantity of steam is sufficient (but not excessive, which is inefficient and can cause other problems). For preconditioners operating at atmospheric pressure, targeting a discharge temperature of 85 to 95°C is practical. If you try to achieve a higher temperature, it is likely that uncondensed steam will exit through the feed inlet, which is wasteful. It can also condense there, causing blockage. (If a temperature greater than 97°C is achieved, then it is likely that uncondensed steam is also present in the product stream and this 2-phase flow is likely to cause problems in the extruder.)

- Design the system with a condensate trap just prior to the preconditioner to ensure a consistent high quality (dry) steam – variations in the quality of the steam will cause variations in temperature and/or moisture content.

Figure 1 shows the results of measurements of the degree of cooking for various residence times in a preconditioner (for the same discharge temperature and moisture content in each case). Note that, initially, increasing the residence time has a major effect on the cook, but then the curve flattens out. As a rule of thumb, a mean residence time of at least 60 seconds is recommended. Residence time of more than 90 seconds will deliver very little additional benefit.

Figure 1- The relationship between the degree of cook and the mean residence time.

Residence time and mixing

We have previously illustrated the importance of sufficient Mean Residence Time. Mean residence time in a preconditioner can be determined quite simply:

Mean Res. Time = Volume of Product in Chamber/Volumetric Throughput Rate.

Figure 2- Residence time distribution curve.

That is, the mean residence time for a given preconditioner (and configuration of that preconditioner) is inversely proportional to the throughput rate. Thus, with other things unchanged, the cook achieved in the preconditioner will decrease as the rate increases – expect the product to change as production rate is increased. We will discuss later the type and configuration of the preconditioner and the impact they have on residence time. Up to this point, we have focused primarily on the mean residence time. In reality, the system behaviour cannot be described by a single value. The residence time distribution (or RTD) must also be considered. A distribution of times stems from the non-uniform flow of material through the system. This type of behaviour is typically represented graphically (Figure 2). The data is often also represented as an “F(t) Curve”, where the “Fraction of material that has exited the system at time t” (F(t) is plotted vs. “t” (see Figure 3). Obviously, a preconditioner with a poor RTD will cause non-uniformity in the output – material which exits the preconditioner too quickly will be poorly hydrated and undercooked. So the RTD should be as narrow and the mean residence time as long as practicable.

Figure 3- A typical F(t) curve for an open system.

Types of preconditioner

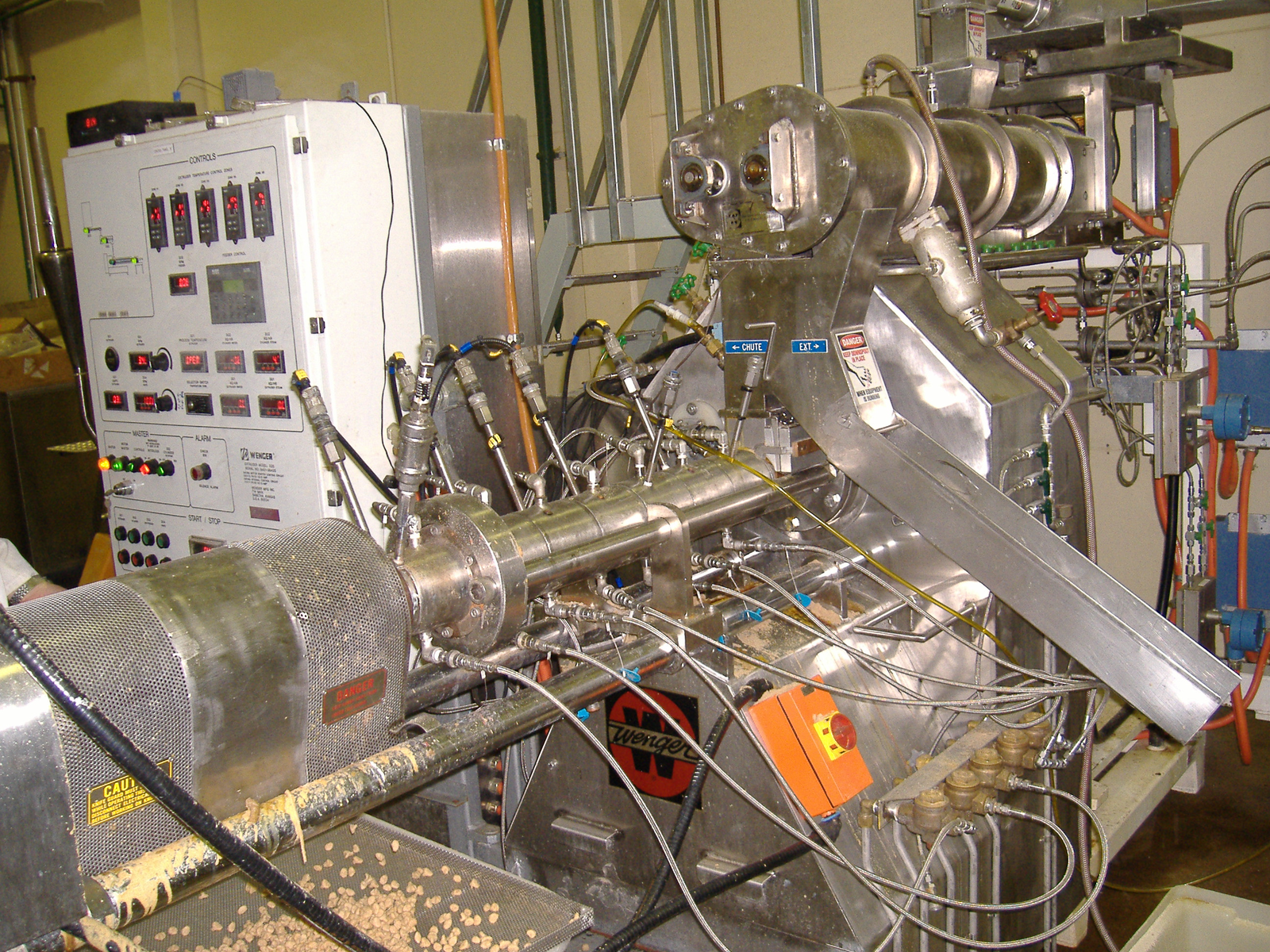

A large number of different types of preconditioner are avail-able on the market. These can be classified in a number of

categories, as summarised in image below (click on icons). To briefly define and compare these designs:

Classification of preconditioners

Pressurised vs Atmospheric – as discussed, temperature is a key parameter in the cooking reaction. The use of a positive pressure in the preconditioner allows the use of an elevated temperature (as high as 115ºC) and thereby promotes an increased reaction rate, i.e. more “cook” for the same amount of time. The negative aspect of operation at an elevated pressure is the requirement of a far more complex sealing arrangement for the infeed and discharge. Pressure feeders or stuffers are also required to force the feed into the system. This higher degree of complexity has limited their use.

Weir-type preconditioners incorporate a weir just prior to the outlet to increase fill in the chamber. The residence time (for a particular throughput rate) is directly dependent on the weir height. It is important to have paddles positioned to effectively sweep just upstream of the weir to prevent “dead” zones.

In open-type preconditioners (no weir), the angle (pitch) of the paddles can be altered with the aim of holding product back to achieve a higher fill in the chamber. General recommendations are:

- Paddles beneath/near the inlet in forward pitch to keep infeed clear

- Last few paddles at the discharge end in forward pitch to positively move material to the outfeed

- Just prior to this, one or two sets of paddles in reverse pitch to “heap” product in the middle of the chamber.

- The remainder of the paddles at neutral pitch (flat to maximise mixing effectiveness).

The paddle configuration has a minimal impact on the residence time for weir type systems. But mixing behaviour is strongly influenced by both the paddle configuration and the paddle speed. For open type systems, however, the residence time is strongly influenced by both these parameters – increasing agitator speed will tend to improve mixing, but it will also tend to decrease residence time. To avoid the compromise between mixing and holding time related to agitator speed, some manufacturers supply Multiple Stage Preconditioners.

Overall recommendations

Choose an appropriately sized preconditioner, configured to provide: 60 to 90 seconds of mean residence time, narrow residence time distribution and effective mixing. Don’t introduce steam too near the entry port, which can result in choking. Introduce water as early in the preconditioner as possible. Adding oil in the preconditioner is not ideal, but if done, add it as late as possible to avoid coating the particles before water has been absorbed. And last but not least, use good quality (dry) steam.

The authors are presenting short courses on “Aquafeed Extrusion Technology” and “Drying Technology” at the Centre for Feed Technology, FôrTek, Norway, in May 2016, plus an Extrusion Course in Thailand in July 2016 (www.fie.com.au/events)