Rapid P test helps to hit a moving target in feed formulation

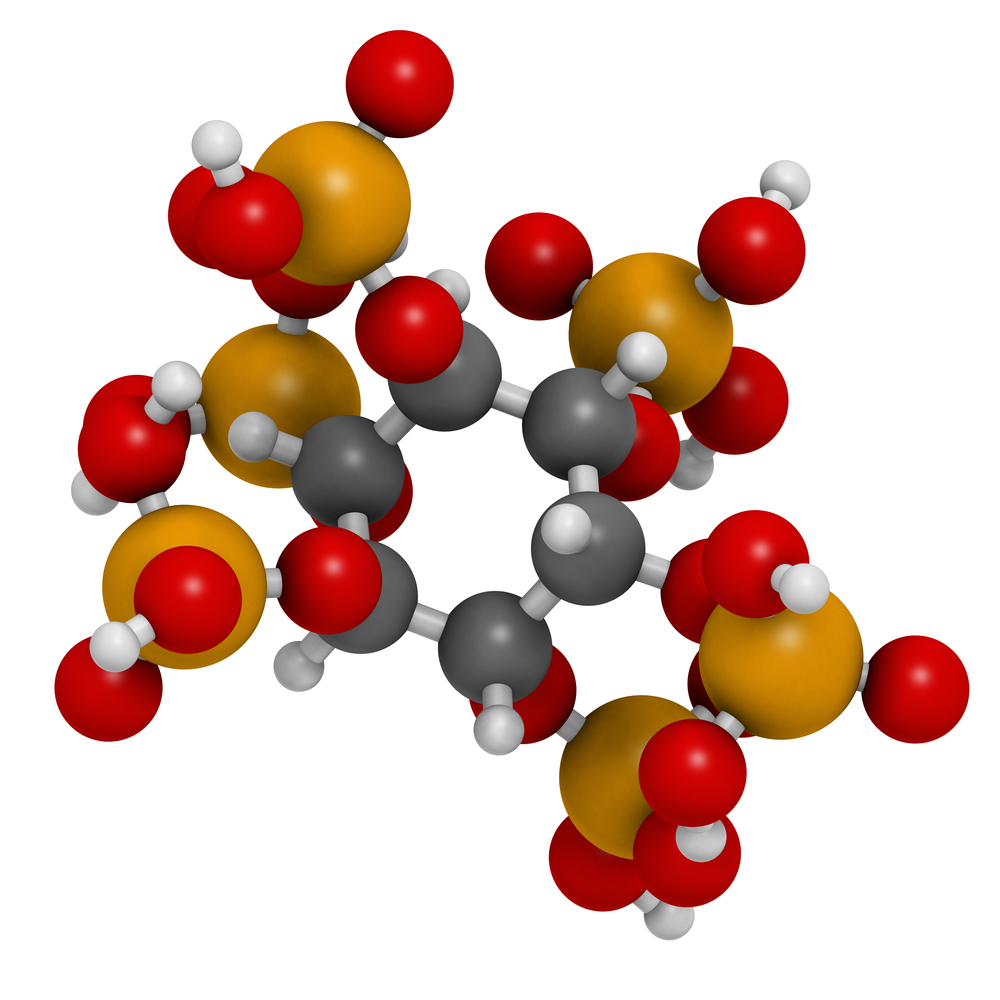

Most people in the feed industry have heard about NIR analysis of protein and fat, but what about testing phosphorous in the form of Phytate-P and Total-P? A new NIR test developed by feed ingredient supplier DSM can help feed producers to constantly track changing levels of Phytate-P and Total-P in raw materials, allowing more precise use of phytase in the feed formulation.

Specifically, the new test data can help nutritionists to calculate the amount of Total-P and Phytate-P based on real-time data instead of index figures of what it should be.

Closer to recommendation

DSM scientist, Raffaella Aureli explained how understanding Phytate-P variability and measuring phytate levels in ingredients will help to maximise the use of phytase supplements to release phosphorus. “Our feed formulation can be closer to the recommendation for the animal and for the users at a premix plant we can include the right level of phytase required to release the phosphorous needed by the animal,” she said. Reliable knowledge of the phosphorous content of raw materials is increasingly relevant for the latest generation of efficient phytase supplements that can make the most of the available substrate.

In line with this trend, there is considerable interest in obtaining precise data on total phosphorus (Total-P) and phytate (Phytate-P) in major feed ingredients. “The nutrient content changes from batch to batch, country to country and, for example with corn, we experience big differences for protein, phosphorous and Phytate-P,” says Aureli. “That’s why it is necessary to have a way of determining the levels for each ingredient.”

Pilot study in Spain

The calibration was tested in Spain where it is used as a customer service formulation. Each time a new batch of raw materials is received the data is used to improve the accuracy of the NIR model. All kinds of raw materials are used in animal feed formulation. “That is why the database behind the calibration is quite large,” says Raffaella. “It needs to accommodate the different nutritional data across poultry, swine and aquafeed for example and the many different ingredient types.”

Available in 2015

The calibration will be made available in early 2015. As availability of the service may vary, the easiest way is to contact a local DSM representative.