Probiotics: How to make them survive pelleting?

Probiotics are increasingly used in animal feed formulations. But the product can only be beneficial for the animal if it survives pelleting. This is especially the case for probiotics that are based on live organisms.

Live yeast is currently used in the animal feed industry, both for ruminants (Pinloche, 2013) and monogastrics (Trckova et al, 2014; Trevisi et al, 2016). However supplementing a diet with live yeast as a probiotic will only be beneficial if it survives the different feed manufacturing processes. Pelleting is the most popular process used in the animal feed industry. At the same time, the pelleting conditions may affect the stability of the probiotic agents, and consequently their efficiency.

Heat and mechanical treatments have physiological and biological impacts on living yeast cells, such as denaturation of some proteins, alteration of enzymes activities and modification of the cytoplasmic membrane integrity. These phenomena are involved in viability reduction that can lead to a decrease of the efficacy in animals. The heat sensitivity of live yeast depends on the strains but also on the cellular phase at the moment of the thermal treatment. Indeed, it is well described that yeast in the vegetative stage is less sensitive to heat. And precisely during the drying process of live yeast, they enter the vegetative stage, allowing them to survive high temperatures (>70°C). That’s why live yeast in dry form is widely used in feed applications. Once ingested by the animals, the yeast recover its full activity. Investment in the understanding and improvement of live yeast resistance in feed processing, in order to ensure optimal efficacy in animals, is therefore very important.

Identifying the parameters

A specific PhD programme has been set up inbetween Phileo Lesaffre Animal Care and Tecaliman (the French Technical Center expert in Feed Technology Sciences). This institute has a well-monitored complete pilot pelleting line composed with a twin-screw feeder, a pilot steam injection unit, a laboratory pelletiser equipped with a fixed disc-shaped die (L 14-175, Amandus Kahl) and a pilot dryer-cooler. This line was selected for its power to repeat and reproduce results, and its industrial representativeness. The experimental design methodology (Goupi, 1996) was used on the pilot line and allowed to identify the parameters of the pelleting process that can challenge live yeast viability and to quantify their impact on live yeast.

Results lead to new product

This scientific strategy, associated with more than 360 pilot trials, allowed modelling the response (yeast viability) as a function of the quantitative effect of the significant factors and their interactions. This model demonstrates that thermal and mechanical constraints are strongly correlated during pelleting and their dissociation is impossible. Furthermore, the main critical parameters identified are: die geometry, temperature and residence time within the steam-injection unit but also moisture content of the feed. Knowing the biological and physico-chemical markers of the yeast cells that are involved in their reaction to thermal and mechanical stress, a specific research programme then allowed developing a highly resistant live yeast probiotic* (hereafter called ‘live yeast‘).

Figure 1 – Evolution of yeast logCFU/g in pelleted feed according to die temperature (°C).

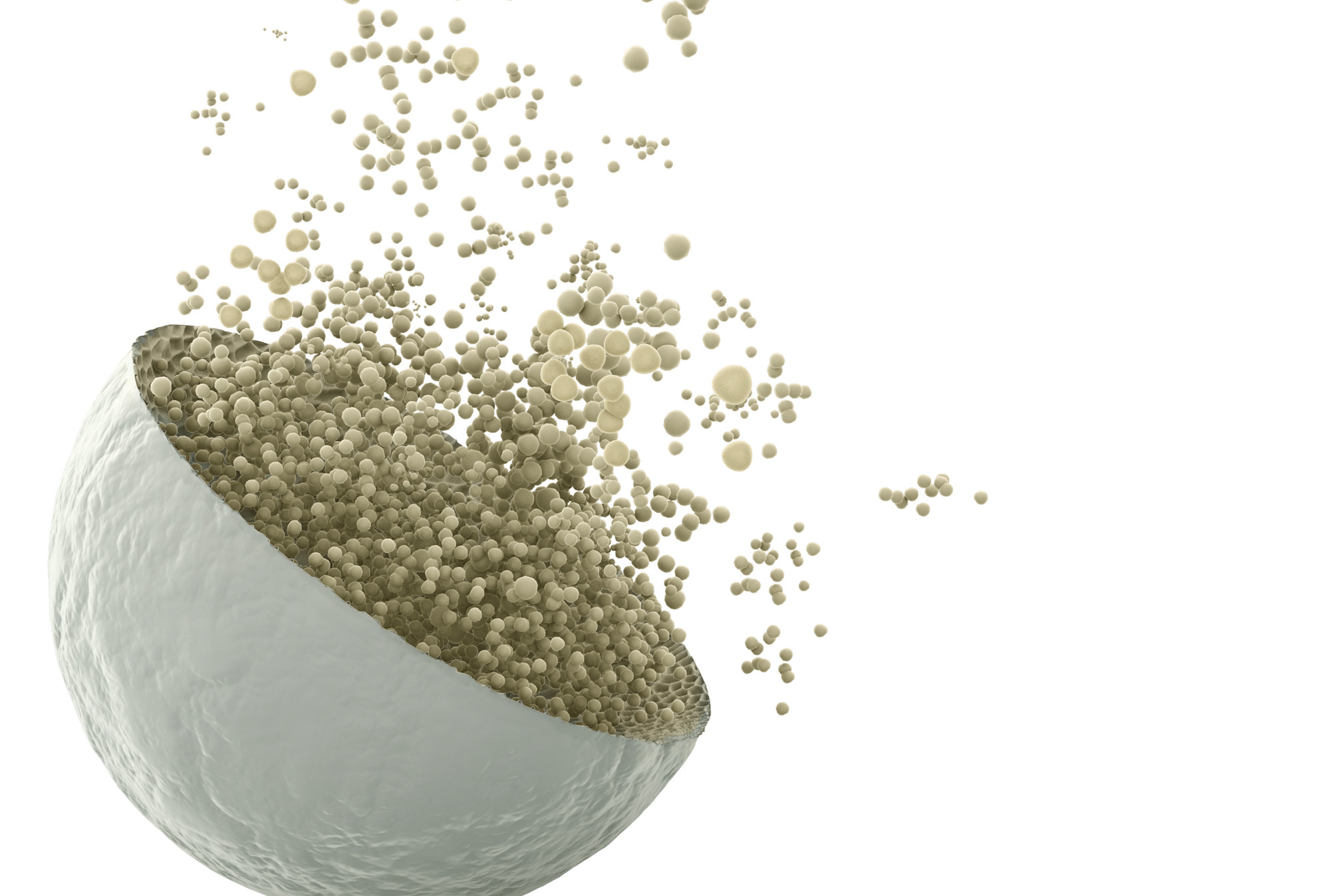

The development of the live yeast was preceded by a meticulous process of screening among the extensive Lesaffre collection of live yeast strains. Following advanced research thus revealed that Saccharomyces cerevisiae Sc 47, whose genome has been fully described, was the best performing one, both for its robustness regarding feed manufacturing processes but also for its remarkable effects on animals’ health and performance. Moreover, its unique HR+ microspherule shape, issued from a specific and sophisticated patented production process, allows it to resist high temperatures, up to 92°C (Figure 1). The specificity of this high resistance comes from the management of the production parameters: a robust strain intrinsically more heat resistant combined with a specific structure (low porosity) that allowed to reach very good resistance during pelleting without any additional coating.

Testing the equation model

The modelling equation, obtained during the preliminary research on the pilot pelleting line, was then compared to a series of tests carried out at factory level (Figure 2), with more than 60 trials in key industrial feed mills worldwide. The correlation value shows that the model correctly estimates the behaviour of the live yeast in industrial conditions at more than 86%. These results show the accuracy of the prediction models established with the pilot tool. Of course, they must also be improved by expanding the experimental area studied, in order to identify the 14% of the missing information. These models takes into account the main parameters, but subtleties such as the parameters of the steam-injection unit and feed composition for example are not fully considered and need to be investigated. One part of the on-going R&D programme aims at enriching this model with new pilot and industrial tests.

Figure 2 – Comparison between log reduction predicted by the model and observed in feed plants.

Tailor made use in feed mill

Knowing the behaviour of live yeast in pelleting conditions is one thing, but it is also important to educate feed millers on how to use the product in all the upstream stages in the feed mill. Only then, an optimal efficacy of live yeast in animals can be ensured. Advice on the use of probiotics should be based on specific conditions and processes in the feed mill, such as the specific pelleting conditions (temperature, humidity, etc). As we have seen, the research carried out over several years, as well as the general improvement of knowledge related to the pelleting conditions, have made it possible to develop precise predictive models for the resistance of live yeasts under these challenging processes. Today, these models allow to create valuable tools in the global support provided to feed manufacturers. This scientific strategy, combining the experimental design methodology and the selection of a convenient pilot tool, shows the high interest for incremental innovation applied to probiotics resistance throughout feed manufacturing process.

* Actisaf® Sc 47 HR+