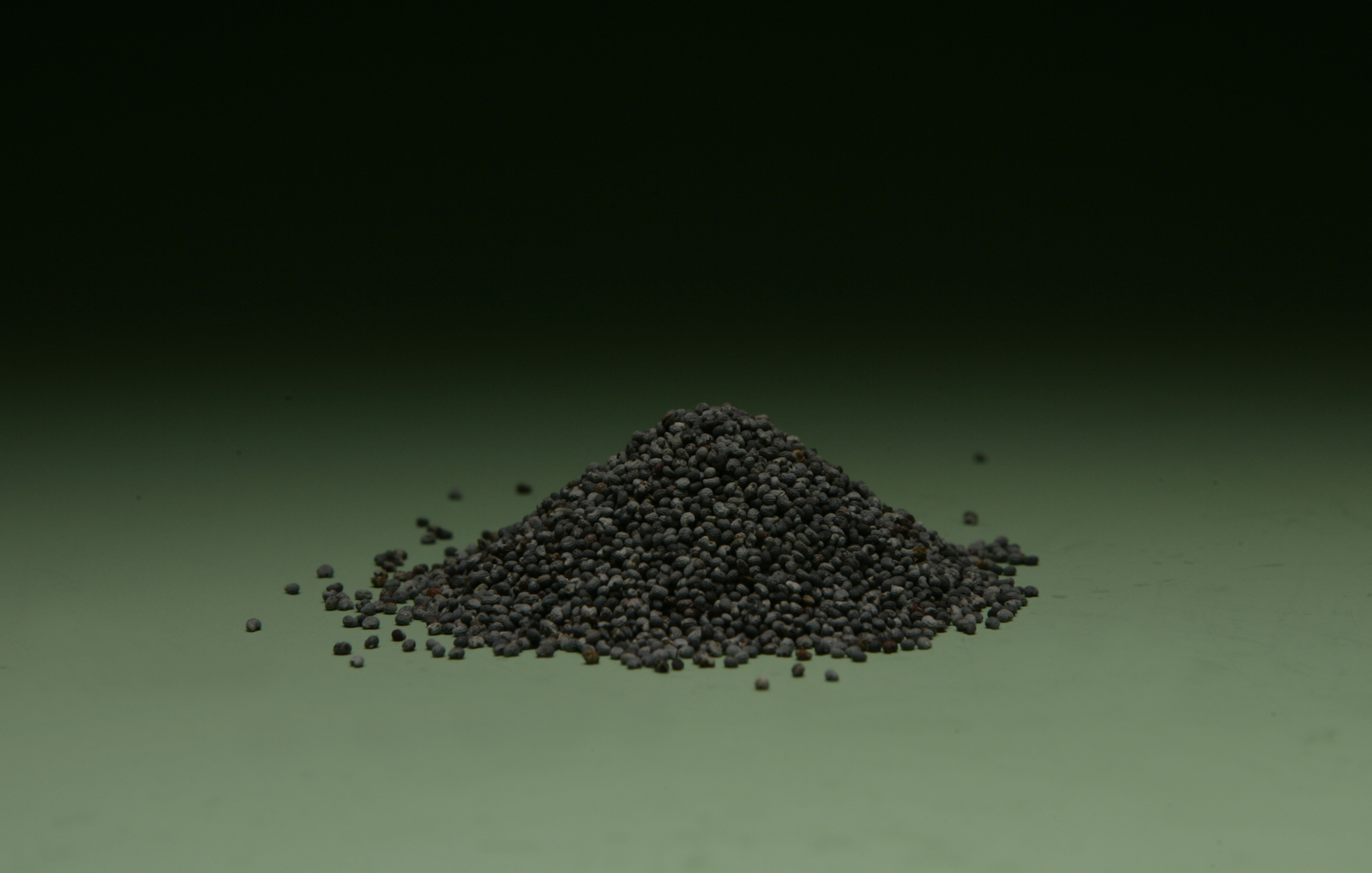

Rapeseed by-products to substitute soymeal

The demand for soy products is high, since meat and bone meal in feed is ?prohibited in the EU. Yet, most of the soy is imported from overseas. Replacing part of the soymeal consumption by locally grown rapeseed products seems to be a promising way to reduce dependency on soy products.

Rapeseed cakes (RC) (the secondary product of screw pressing rapeseed) and extracted rapeseed meal (the product of chemical extraction of rapeseed) are rich in proteins, so suitable for high-production dairy cows. Extracted rapeseed meal (ERM) has been used for a long time in Germany and in the Scandinavian countries where ERM is used as a fully-fledged, 100% substitute of soymeal in feeding high-production dairy cows. RC have a similar nutritional composition as ERM, also making it a fully-fledged substitute of ERM. Moreover, thanks to the clean mechanical extraction of vegetable oil, they do not contain any residues of chemical solvents, which are used in chemical oil extraction. Also, the higher content of fat and thus a higher energetic value of the cakes is an undisputable advantage. Cakes are not used in the fodder for ruminants as widely as ERM, particularly due to the low production of cakes. However, they play an important role in animal nutrition.

Study in thermal treatment

In a recent study, two different cakes were compared. One was produce by a technology from the company Farmet, using cold-warm pressing (CWP). The other cake was derived by using a two-stage pressing with extrusion EP2. The cakes were compared with extracted rapeseed meal. In CWP technology, rapeseed is cold-pressed at first stage and then heated in a stack cookers followed by being warm-pressed in the second stage. With the EP2 technology, the material is first cold-pressed, then heated and extruded in the extruder and then pressed in the second stage. The extracted rapeseed meal was wet-extruded: the rapeseed meal was first heated and humidified in the steam preconditioner and then extruded. The content of crude protein (CP) in the dry matter in the compared materials was similar. The comparing temperature for the meal was set at the temperature in the last working chamber (the material temperature is estimated to be lower) and for the cakes the temperature of the cakes was set at the output from the final press.

Crude protein modification

The aim of the study was to determine the transformation of protein fractions according to The Cornell Net Carbohydrate and Protein System (CNCPS). In particular, the transformation of fractions B2+B3 was monitored (these fractions affect the quality of the by-pass protein –protected from rumen degradation) in relation to the temperature in the individual technologies. Target value of experiment for B2+B3 fractions was set at 22% in dry mater (75% of CP content is rumen protected). Figure 1 shows the effect of the temperature of the cakes on protein transformation where the ratio of fractions B2+B3 increases with rising process temperature. In the CWP technology, there is a sharp increase in the fraction transformation in favour of B2+B3 starting at the temperature of 115°C. Therefore, pressing at temperatures below 115°C does not contribute to the nutritional value of the cakes. When the temperature exceeded 125°C, the target value was achieved. The EP2 technology shows a much more linear progress of the transformation when fractions B2+B3 stabilise at the value of 26% starting at the temperature of 120°C, which significantly exceeds target value. Extrusion of extracted meal produces a product that has better parameters than other technologies. However, higher energy inputs are required, which can be more expensive in the end.

Furthermore, Figure 1 implies an economic benefit of warm-pressing with the use of a stack cooker. When compared with the extruded extracted rapeseed meal, the sum of input energy in the case of rapeseed cakes is much lower. The nutritional parameters of the protein fractions in rapeseed cakes from the final press during warm-pressing are comparable though. When processing the rapeseed meal, 80 – 100 kg of steam was used per 1 tonne of material and 40 – 50 kW/t of material during extrusion. To process rapeseed cakes by warm-pressing, only the steam in the stack cooker was used for heating. However, its quantity was not measured precisely. The energetic intensity of warm-pressing is lower when pressing is compared to extrusion.

Figure 2 does not show a significant dependence of changes in fraction C (indigestible protein fraction), which means that there is no considerable degradation of proteins even when the maximum temperature is reached. Therefore, it is possible to assume its good intestinal digestibility in case of protein being not degraded in the rumen.

Conclusion

To reduce dependency on soymeal in animal nutrition there is great need for developing new sources of protein. The application of thermal treatment of rapeseed cakes or extracted rapeseed meal, described in this article, can significantly improve their nutritional value by shifting protein fraction to increase by-pass protein content. At the same time, the oil yield in oilseed pressing technologies also increases when heating by extrusion or a stack cooker is applied. The measured data showed the improvement in nutrition values of rapeseed cakes and extracted rapeseed meal, but appropriate choice of technology depends on specific situation and customers’ requirements.