4 factors to consider when including trace minerals in feed

While much has been written about the essential role trace minerals play in livestock performance, little attention has focused on the actual delivery of the trace minerals to the animal. Simply including trace minerals in the animal’s diet is not enough. Minerals must be delivered at the proper time and at the right level to deliver the desired performance effects.

Several factors challenge trace mineral supplementation. These factors include the mineral source, physical properties, accurate weigh out of trace minerals within the mix, proper mixing and the chemical and positional stability of the trace mineral within a premix or complete feed mixture. Achieving a precise approach to trace mineral supplementation requires special attention to how different factors affect the actual level of trace mineral delivered to the animal.

Below are 4 points to consider when steering trace mineral supplementation strategies.

Trace mineral form and stability

Trace mineral form and stability

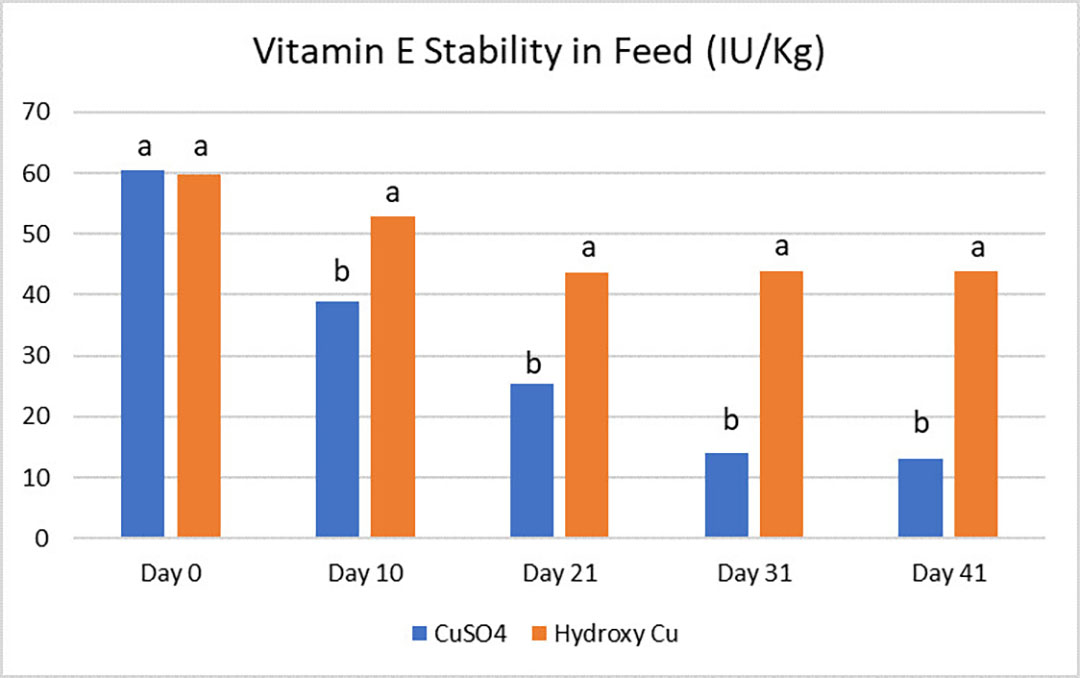

Particle size, particle size consistency, hygroscopicity, reactivity, dustiness, and bulk density can influence a trace mineral’s form and stability. To assure proper mixing, a trace mineral product should contain particles that are ideally 150–250 microns in size with very little variation. This is critical to achieving a uniform mix and for maintaining trace mineral positional stability in final packaging. If particle size varies widely, smaller particles will segregate and move to the top or bottom of the package (bulk density dependent) when vibration occurs, such as during transport. A selected trace mineral should not be hygroscopic, which can chemically attract moisture into the trace mineral product or complete feed causing clumping and or destruction of essential nutrients in the premix or complete feed. Certain inorganic trace mineral forms are classified as pro-oxidants, which means they can promote accelerated oxidation in the premix or complete feed, facilitating the destruction of essential nutrients which are added to the complete feed like fat, vitamins, microbials, enzymes, etc. (Figure 1).

Figure 1- Vitamin E stability in feed.

Values (a,b) are significantly different (p < 0.05)

Trace mineral form and inclusion within a mix

Trace mineral form and inclusion within a mix

Significant variances in different forms of trace minerals can impact formulation and adversely affect how much of an individual trace mineral is added to a mix. Table 1 clearly shows how the addition level of an individual trace mineral can vary within a complete feed formulated to deliver 100 ppm of zinc. It is also important to consider the very small amount that individual trace minerals represent within the overall volume of a complete feed mix. Using the example above, the actual amount of trace mineral added per ton of complete feed would vary from a low of .14 kgs to a high of .83 kgs (.014-.083% of the total mix) based on the trace mineral form selected. Given the small volume of trace minerals represent in the final feed, care must be taken to ensure that required trace minerals are being properly selected and accurately weighed within the premix/complete feed.

Mixing and sampling

Mixing and sampling

It is well known that care must be taken when adding micro ingredients to a premix or complete feed to ensure uniform mixing. The timing of when trace minerals are added to the mixing sequence and/or the total mixing time can adversely affect uniform distribution of essential trace minerals within the final feed. Compounding this challenge is the lack of precision typically offered by laboratory analysis which can vary by 10-20% depending on the trace metal being measured. When sampling trace metals within a mix, a good practice is to avoid the first and last 10-15% of product being discharged from the mixer. Samples should be pulled from the middle portion of the mix and analysed using wet chemistry protocols. To consistently achieve highly precise mixing, it is best to establish a defined protocol clearly highlighting trace mineral selection and weighing criteria along with when the trace mineral(s) are sequenced within the mixing process and mixing time.

Chemical stability of essential nutrients in premixes and feeds

Chemical stability of essential nutrients in premixes and feeds

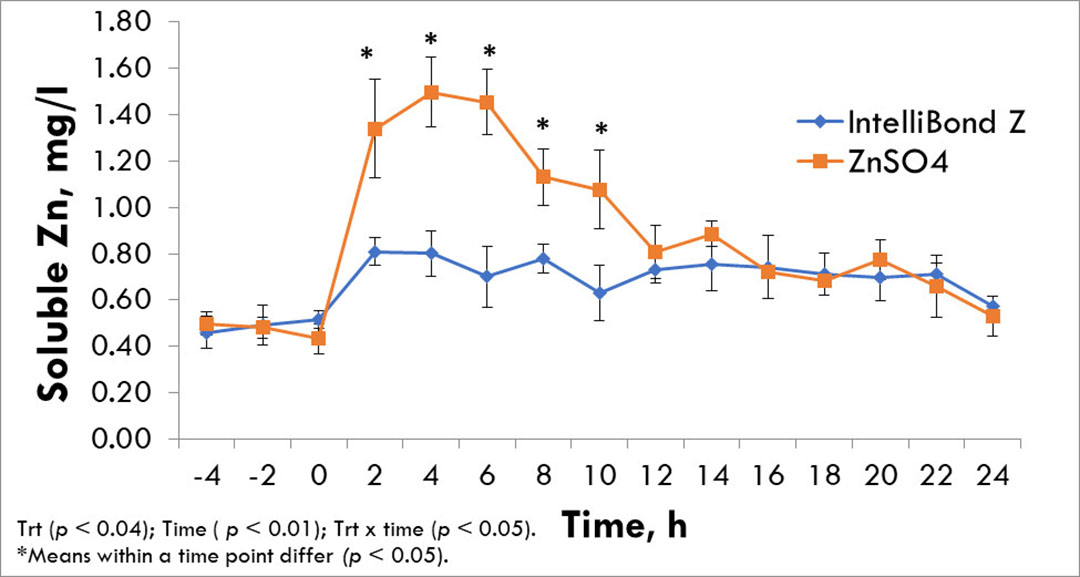

Trace minerals are chemical compounds that can vary in their solubility and reactivity within the premix/complete feed. Typically, inorganic trace mineral sources (sulphates, chlorides, etc.) have very high solubility/reactivity compared to hydroxy trace minerals (IntelliBond), which have very low solubility/reactivity in the feed and in the animal. High levels of reactivity can have a negative impact on the stability and efficacy of many essential nutrients (Figure 2) added to the mix such as vitamins, fat, enzymes, probiotics, trace metals, binders, etc. Solubility concerns become even more important if feeds are being pelleted, given the injection of moisture via steam into feed during processing. Such moisture-related processes can increase the reactivity of inorganic trace mineral forms, resulting in more essential nutrient destruction.

Figure 2 – Zinc solubility.

Achieving a higher level of precision trace mineral nutrition

To help producers mitigate the effects of the challenges described above and support both animal performance and producer economics, Selko developed IntelliOpt — a cost-effective solution to achieve a higher level of precision trace mineral nutrition in premixes and complete feeds. The IntelliOpt product portfolio offers producers, pre-mixers, and compounders a species-specific blend of IntelliBond, Optimin, and other essential trace minerals precisely formulated to deliver optimal animal performance.

All IntelliOpt blends are formulated based on the knowledge and insights of leading industry groups and academic professionals with a keen eye on ensuring optimised animal productivity and well-being. Individual blends are manufactured by Selko to ensure that all critical nutrients are present in the right form and amount to support trace metal availability to animals.

The selection of a trace mineral source is an important decision to support productivity and health. However, knowing how that source was added and mixed, along with its impact on other essential nutrients in the feed, are equally important parts of an effective precision nutrition strategy. Ultimately, the best trace mineral source is of little value if it is not consistently delivered in the correct amount and form required for peak animal performance and health.