Anti-nutritional factors: Better predictions minimise nutrient losses

While we mostly focus on the amount of nutrients we need in the diet to meet an animal’s requirements, we sometimes forget the amount of nutrients we are losing due to the variability of anti-nutritional factors. If we have a better grip on this variability, it will directly benefit animal performance and help to fine-tune enzyme supplementation.

Formulating animal diets is based on price, available raw materials, the animal’s nutritional requirements and more. Any unnecessary losses due to indigestibility is simply a loss of money for the farmer (loss of nutrients itself and loss of animal performance combined). This means that we have to better understand and control this ingestible fraction of animal feed.

Any diet is 100% digestible?

In feed formulation, we always have to keep in mind that the digestible nutrients were defined on top of an standard optimal feed. But do you know how much of the nutrients you formulate are actually utilised by the animal? Depending on the actual quality of raw materials, it may be different than our expectations. On average, without the use of any digestibility enhancers, we define the following percentages to the digestible and the indigestible part of the diet:

- Around 70-80% of the feed is the so-called ‘digestible fraction’. This part of the diet consists of protein, amino acids (AA), starch, fats, sugars, vitamins and minerals that are well digested and assimilated by the animal. This fraction delivers the nutrients needed and hence contributes to the maintenance, health, welfare and performance of the animal.

- Around 20-30% forms the ‘indigestible fraction’. This part can be divided into 2 groups. Firstly, the anti-nutritional factors (ANFs) such as phytate, NSPs (like arabinoxylans) and NDF (Neutral Det Fibre). Secondly, we have nutrients that, by different reasons, are ‘simply’ not well digested or taken up by the animal, such as indigestible AA (total AA minus digestible AA), part of fat and the phosphorus as locked by plants in the form of phytate. This fraction doesn’t contribute to the nutritional value. The ANFs can negatively affect digestibility, feed intake and hence performance of the animals.

What are the common ANFs?

There are a few common ANFs that need special focus. Starting from NSPs (Non Starch Polysaccharides): they are naturally part of the plant cell wall of cereals and legumes and are made of complex heterogeneous networks primarily consisting of cellulose, and hemicellulose and pectic polysaccharides. NSPs have a strong negative effect on feed digestibility, nutrient release and availability, gut health and ecology.

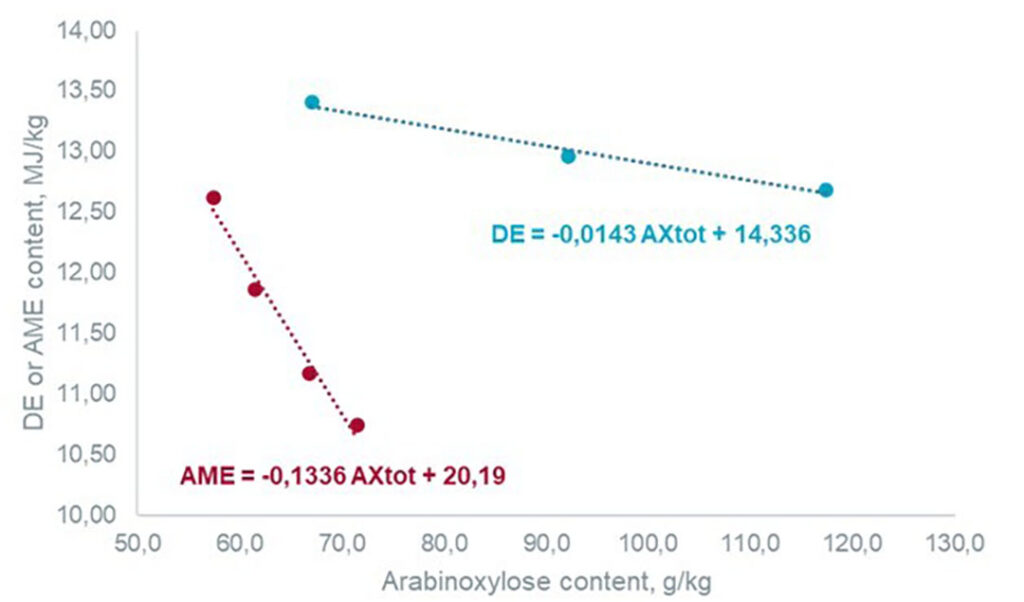

NSPs also increase losses and disruption of endogenous enzyme functions. In vitro data from Meng et al. (2005) showed that NSPs decrease starch and nitrogen digestibility, directly impacting AMEn (apparent metabolisable energy, N-corrected) to the bird. A large part of the NSPs are the arabinoxylans (AX), known to evoke antinutritional effects in the gastrointestinal tract (GIT) of pigs (blue line) and poultry (red line), as shown by Sun et al. (2019) and Cozannet et al (2017), adapted in Figure 1.

Figure 1 – The effect of AX content on AME for broiler (in red) and DE for swine (in blue).

Another important ANF is phytate (or phytic acid). This is the principal storage form of phosphorus in many plant tissues, especially bran and seeds. Phytate hinders the digestibility of phosphorus (P), calcium, amino acids, protein and thus, energy. It also increases the release of inorganic P excretion to the environment, which is not wanted from a sustainability perspective. On average, for each 1% phytate in the diet, the feed digestibility decreases between 0.49 to 0.89% on organic matter digestibility or AME (source: Adisseo-CERN studies).

Better understanding of ANFs

A significant part of ANFs can be broken down with the application of enzymes. The application of phytase is the most commonly used exogenous enzyme in the feed for monogastric animals to degrade phytate, limiting the anti-nutritional impact and facilitating the release of phosphorus from plant-based raw materials. When more phosphorus can be made available from the raw materials, less mineral phosphorus has to be added in the formulation. Also, the application of NSP degrading enzymes in pig and poultry diets is a growing market. Certain indigestible nutrients can be released by adding certain enzymes to the feed.

The application of enzymes makes diets better digestible and profitable. But there are many enzymes available on the market and nutritionists, purchasers, and plant and quality managers need more than just an amount of enzymatic proteins. They need specific enzymes, and support and to optimise the use of enzymes and maximize return on investment. This requires us to step up our knowledge of ANFs and their components, and find ways to better predict the ANF content of raw materials. When we have this better understanding of the presence of ANFs, how they react to specific enzymes, etc., the application of enzymes can be more precise and we can better predict the effect of these enzymes, decreasing carbon footprint, and increasing profits.

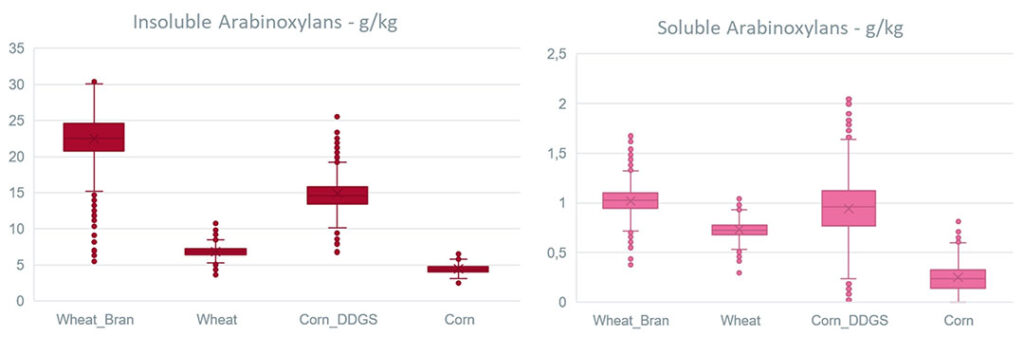

This starts with better understanding ANFs. Not all ANF fractions react the same to enzymes. For example, cereals and protein meals have key differences in arabinoses and xyloses. In protein meals, the sugars arabinoses and xyloses come from pectin and are therefore not sensitive to pure xylanase. In addition, the ANF contents of raw materials can vary considerably in practice. This is also the case for phytate (phytic acid). This is not only seen between different types of feed ingredients, but also in the same type of material, depending on harvest, origin, and overall quality of the raw materials we are dealing with. Working with averages may lead to over or under supplementation of nutrients and enzymes, as the variability of ANFs can be up to 20%. Adisseo analysis showed considerable variability in insoluble AX and soluble AX in several cereals, as shown in Figure 2.

Figure 2 – The variability of insoluble and soluble AX in different feed ingredients.

(Source: Adisseo-CERN studies)

Introducing the Feedase predictor

Because of the negative effect the ANFs have, it is important to measure them. When formulating diets, you simply need to know the nutritional values AND the anti-nutritional factors. To do so, Adisseo has analysed more than 400 different samples from 18 different raw materials, and 4 different harvests (2019-2022) to create new NIR calibrations for total AX, insoluble AX and soluble AX in corn, corn DDGS, wheat and wheat bran, to be used for FOSS and Bruker desktop NIR equipment. These new parameters, plus the phytate predictions already available, are shown in the Precision Nutrition Evaluation (PNE) tool from Adisseo (the nutritional database based on NIR data, as part of the so-called ‘ANF pack’).

The PNE data, in combination with the in vivo trials on Rovabio resulted in a new tool to improve the accuracy of the nutritional matrix for the enzyme(s) used. The Feedase Predictor has been developed by Adisseo to compare the enzymatic potential under different feed programmes or comparing different Adisseo enzymes when using the same formula.

Thanks to this new prediction tool, nutritionists can make a customised matrix based on specific PNE results around ANFs from their own scanned raw materials or use the average prediction data (coming from Adisseo in vivo performance and digestibility studies performed all around the world and under different raw material conditions) which is already pre-loaded in the tool.

Conclusion

Precision nutrition is all about knowing the nutritional values AND the impact of anti-nutritional factors. While enzymes are commonly used, the variability of the ANFs present can lead to over or under supplementation, which can lead to unnecessary costs or underperforming birds.

The new Feedase predictor tool can be used for different poultry species, feed programmes and all Rovabio products. It allows us to extract the full feed value, reduce feed costs and minimise losses (which is positive for the animal as well as from a sustainability standpoint). In a time where we are looking for each cent of cost reduction, this is a true added value for poultry producers.

Less waste of nutrients + better nutritional evaluation = better sustainability and profit.