Application of soy protein concentrate in poultry pre-starter feed

Newly hatched birds have an under-developed digestive system and require highly digestible protein ingredients. Among commonly used plant protein sources, soy protein concentrate is an excellent plant protein ingredient for poultry pre-starter feed.

Survival rate of post-hatching birds and uniformity at market size are the key elements in broiler farming systems. Obviously, both factors are related to early feeding, i.e. the feeding during 0-7 days post-hatching. For post-hatching birds, it is important to start feeding as early as possible to provide exogenous nutrients and energy so that the birds can use the yolk-sac energy for improving immune function. For this reason, the concept for a pre-starter feed has been developed and adapted by some poultry feed companies. Pre-starter feed for broilers is designed with high nutrient and energy value using easily digestible protein sources by supplementation of various additives. It is meant to feed birds after hatching until 7 days of age (i.e. 200g feed/bird) with the aim to improve survival rate and immune function, increase uniformity and feed utilisation efficiency and to reduce the time of rearing to market size. Since the banning of antibiotic growth promoters in animal feed it is even more important to apply pre-starter feed concepts in order to maintain economic profitability in poultry farming. Fish meal is commonly used in poultry feed. However, fish meal supply is limited and the price of fish meal is increasing. Alternative protein sources are needed as a replacement for fish meal. In piglets, literature studies showed that replacing fish meal by soy protein concentrate (SPC) maintained or improved growth performance. SPC has a comparable protein and amino acids (AA) composition as fish meal, it is an excellent alternative protein source for fish meal in poultry feed.

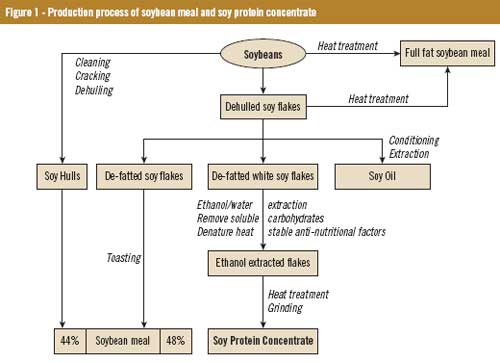

SPC production process

Raw soybeans contain high levels of both heat stable (including mainly soy antigens and oligosaccharides) and heat labile (mainly trypsin inhibitors and lectins) anti-nutritional factors (ANFs). Soy protein product quality is, therefore, closely related to the production process. Both defatted and full fat soybean meal are produced by heat treatment, this process can reduce the levels of heat labile soy ANFs, however, the heat stable soy ANFs are not removed.

Feed grade SPC is classically produced by ethanol/water extraction of low temperature processed soy white flakes, followed by proper heat treatment. In this way, both heat stable and heat labile ANFs are removed (Figure 1).

As soluble carbohydrates are removed by ethanol/water extraction before heating, this results in reduced probability of Maillard reaction and improved product quality. SPC is characterised by high protein content, high amino acid digestibility, low indigestible carbohydrates content, low in both heat stable and heat labile soy anti-nutritional factors. The nutritional value of high quality SPC is comparable to fish meal in feed for young animals.

Effect of SPC processing

Trypsin inhibitor activity (TIA) can reduce the digestibility of protein and decrease the growth performance of chickens. It was reported that high TIA in under-processed soybean meal reduced the weight gain of chickens. Optimal growth rate was observed at a TIA level of 1-3 mg/g. Overheating, however, reduced weight gain of chickens due to reduced protein quality.

Lectins bind to the small intestine mucosa cells and cause severe disruption. This damages the intestinal surface and causes reduced nutrient absorption and consequently decreases the growth rate. In poultry, it was observed that removal of lectin from raw soybeans improved true metabolisable energy (TMEn) and growth performance.

Poultry lack specific enzymes to hydrolyse oligosaccharides, and the presence of alpha-galactosides causes a reduction in the metabolisable energy of soy, lower fibre digestion, and acceleration of the feed transit in the intestinal tract. In addition, the passage of alpha-galacto-oligosacchrides into the caeca leads to fermentation and disturbance in the digestive tract, causing flatulence, wet droppings, and diarrhoea. The differences in some anti-nutritional components between SBM and SPC is illustrated in Table 1.

Literature studies showed that removing oligosaccharides from SBM resulted in an increased TMEn, digestibility of dry matter and fibre. Coon et al. (1990) reported that removal of alpha-galactosides from soybean meal by ethanol extraction increased true metabolisable energy by 25%. To achieve the maximum true metabolisable energy, it is recommended to remove more than 80% of the stachyose from soybean meal.

As shown in Table 2, a SPC based diet has higher metabolisable energy (MEn) values as compared to a SBM based diet, especially for young birds at 0-4 days post-hatching. Young birds at 0-4 days after hatching have an under-developed digestive system and need easily digestible, high metabolisable energy diets to meet their energy requirement.

Yu et al. (2002) determined the effect of protein sources on apparent ileal protein digestibility of diets for 3 and 6 week-old broilers. In this study, tested protein ingredients were used as the sole protein sources in the diets. The results showed that a SPC based diet had improved protein digestibility compared to a SBM based diet, especially for young animals (Table 3).Batal and Parsons (2003) compared apparent amino acids digestibility in chicks fed diets using either SBM or SPC as protein sources. The results showed that apparent amino acids digestibility was much higher for a SPC based diet than a SBM based diet (Table 4).

Application of SPC in poultry

Literature studies and practical experiences have demonstrated that removal of anti-nutritional components in soybean meal improved the growth rate of chickens. The advanced processing technology for SPC production has eliminated anti-nutritional factors, reduced level of indigestible carbohydrates, increased protein content and amino acids digestibility. This makes SPC a good alternative protein source for fish meal in poultry feed. The use of SPC in poultry pre-starter feed will help to reduce the stress in the early stages, improve health status and can be beneficial to growth performance in a later stage.

In addition to a high level of anti-nutritional factors, the high kalium (K) in soybean meal may also limit its inclusion in poultry feed because high K may be associated with wet litter problems. When expressed as per unit ofprotein, K content in SPC is lower than in soybean meal. Using SPC, therefore, can reduce the K content in the diet.

Another advantage of SPC compared to soybean meal is its low nitrogen-free extract and soluble non-starch polysaccharides (NSP) content. It is generally accepted that NSP, especially soluble NSP, can increase viscosity and reduce the digestibility of nutrients. Assuming the use of SPC and SBM respectively to provide 10% dietary CP, the nutrients provided by these two soy protein products are presented in Table 5. Clearly, use of SPC as protein source reduces ash, moisture, nitrogen free extract (soluble NSP) and potassium content in the diet compared to the use of soybean meal.

Beneficial to intestinal health

In an antibiotic free diet, to limit the growth of microflora in the intestine, it should be formulated with low fermentable carbohydrates and low indigestible proteins. In broilers it was reported that diets formulated based on fishmeal or potato protein exhibited significantly higher C. perfringens population in the intestinal microflora compared to a SPC-based diet; whereas no differences in lactic acid bacteria population were observed between the different dietary protein sources. Massive propagation of C. perfringens is associated with necrotic enteritis in broilers. This implies that fish meal and potato protein concentrate may stimulate the growth of pathogenic bacteria due to the higher levels of indigestible protein; whereas SPC depresses the growth of pathogenic bacteria and does not harm benign bacteria, i.e. lactic acid bacteria (Figure 2).

Pre-starter feed during transportation

It normally takes 24-48 hours before newly hatched chicks receive their first exogenous feed and water. The benefits of early provision of nutrients in newly hatched chicks have been well documented in literature. It can stimulate feed intake, improve gastrointestinal tract development and the immune system. Early protein intake might stimulate protein satellite cells, which are myogenic precursor cells and instrumental in determining later stage muscle development. Early provision of both energy and water supports the chick’s thermoregulation.Early feeding can be started during transport of chicks from the hatchery to the farm. It is reported that early access to semi-moist diets containing high quality protein sources such as SPC for day-old chicks stimulates gastrointestinal tract development and prevents dehydration during transport.

Advantage of SPC in young turkeys

A recent study reported that young turkeys fed a SPC based diet had significantly improved growth performance when compared to a SBM based diet. Birds fed the SPC based diet had low ileal tissue mass, dry matter content of digesta and rate of bacterial production of short chain fatty acids in the caeca. The authors suggested that the improved intestinal physiology and growth rate in SPC treatment is related to reduced soy oligosaccharides content in the diet. This study demonstrated that using SPC as protein source in young turkey’s feed may lead to economical benefits.

Summary

Soy protein concentrate is a high quality protein ingredient suitable for poultry pre-starter feed. It’s high protein digestibility and high ME value makes it an ideal protein source for pre-starter feed for young birds at 0-10 days after hatching.Poultry pre-starter feed is more expensive than standard poultry feed. However, by using the high quality pre-starter feed, the high feed cost is justified by improved productivity leading to an overall benefit.