Optimising nutrient density in a volatile market

The profitability of broiler production, expressed in its simplest form, is the value of the end product minus the input costs to produce that product. Of the input costs, feed is the major component. The ultimate challenge is to reduce input cost to a minimum, without compromising biological performance and profitability. A modelling approach can help to better calculate optimum diets.

By Dick Ziggers

Breeding companies use very sophisticated programs to select the best bird for future performance. It takes four years before the current pedigree birds produce the commercial broiler. Therefore genetic companies spend a lot of effort in anticipating future developments in management, nutrition and broiler performance. The improved breeder and broiler performance will change the future nutritional responses and therefore influence the nutritional strategy that maximises profitability. This emphasises the importance for poultry producers and nutritionists to explore the genetic potential of the continuously improving modern breeder and broiler and tailor specifications accordingly. It also represents one more factor that a nutritionist must account for when formulating. Feed is the major component of input cost, normally accounting for up to 70% of the total production cost. For this reason, any review of input costs and profitability will include a review of feed costs as a primary component of the exercise. Thus choosing nutrient levels can have a huge impact on cost, but more importantly on profitability. It is the responsibility of the nutritionist to decide on nutrient levels that will not only optimise biological performance but also that will maximise profitability. Prices of raw materials are increasing and therefore so do feed costs. It is therefore tempting to reduce the nutrient specification of the feed to reduce feed cost per tonne. But one should first evaluate the full impact of such a decision upon margin over feeding cost. The desire to minimise feed cost per tonne needs to be balanced against maintaining or maximising margin.

USA industry trends

Over the last decade, poultry breeding companies have achieved an average annual improvement in broiler growth rate to 42 days of about 50-60g or one day of growth per year. During this same period, white meat yield has increased 3.0%-3.5% on average. Simply put, today’s broilers grow faster with more muscle development, but consume less feed per unit of gain. Because amino acids are required to grow muscle protein, it is reasonable to infer that there would be a change in the dietary requirements for these modern broilers.

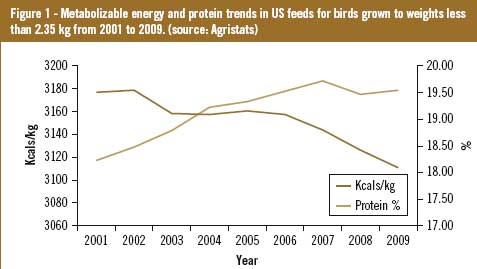

A look at USA industry trends since 2001 shows how dietary nutrient density has been adjusted to account for changes in genetic potential and other market factors. Figure 1 shows the trends since 2001 in energy and protein density of the diet of birds grown to weights less than 2.35 kg (source: Agristats). The data represent weighted averages of the nutrient levels across the entire grow out period (feed volume × energy content). The graph clearly visualises that energy density has followed a gradual decline, while protein levels have tended to increase. In 2008, energy density was lower than at any other point since 2001. This coincides with periods of extremely high corn and fat source prices.

Aviagen has published nutrient density recommendations for diets fed to broilers in the starter, grower and finisher period (Table 1), with the comment that the nutrient levels need to be adjusted to maximise profitability under local conditions. The ideal energy and amino acid levels will depend on the raw material prices as well as product mix and prices for any particular operation.

Nutrient density in volatile markets

Over the last 18-24 months commodity prices have not only shown marked increases but have also become more volatile. Radical fluctuations of corn, soybean and soybean oil could be observed. It is not only the prices of feed ingredients that fluctuate. The prices of whole carcasses, breasts, thighs and wings also vary quite markedly at times. Clearly the nutritionist has a multitude of variables to take into account when deciding on energy and amino acid levels for his feeds.

Alterations in energy and amino acid density will affect not only performance but also have an impact on profitability. It becomes very difficult to make the right decision on nutrient density with high volatility in factors affecting profitability (raw material prices, meat prices etc). Nutritionists often resort to their intuition to make decisions. Rising feed prices then result intuitively in reducing nutrient density to control feed costs. This may work on the short term, but it may have detrimental effects on profitability.

Margin over feed costs

When looking to minimise feed cost, it is important to appreciate the effect on margin. The diagram of Figure 2 shows that as nutrient level increases, feed cost increases. However, due to improved bird performance the revenue from the birds also increases, and therefore margin over feeding cost is improved. The maximum margin is clearly not produced by minimising feed cost (indicated by red circle), but is achieved at the point where the difference between revenue and cost is greatest as is illustrated by the zone of maximum profitability.The producer should aim to feed the bird to ensure margin is in the maximum zone in the diagram. To do this, maintaining or increasing dietary nutrient density will often be justified. Lowest feed cost does not necessarily produce maximum margin.

The amino acid density of the feed will have a major influence on margin achieved and profitability. But balanced protein is only one of the two main components of the nutritional package. Energy also needs to be considered. The growth of the biofuels industry has resulted in feed energy prices becoming more affected by oil prices than conventional commodities markets. With an increase in the use of cereals and feed fats for the biofuels sector, and firm oil prices, energy will likely continue to be relatively expensive.

Modelling approach

With protein and energy being the two most important constituents, but also the most difficult to predict constituents of poultry feed, Aviagen broiler nutrition research has developed a model to better manage profitability with keeping in mind the economic factors involved as well as bird health and welfare. A multitude of studies have been conducted to determine the impact of energy and amino acid density on live and processed yield results, which has resulted in a bio-economic model called BEEP (Broiler Economics for Energy and Protein). The model contains pooled data from 11 trials conducted within the last four years in various regions of the world. In each of the trials the ideal protein concept was applied and amino acids were kept in the ratios shown in Table 2. As new trials are run they are added to the database. A variety of energy and amino acid levels were tested using Aviagen’s recommended levels (Table 1) as a reference (100%). Table 3 shows the range of energy and digestible lysine levels tested in each diet.The first step in the model is to clearly define the biological response of the broilers to both metabolisable energy (ME) and amino acid density. Stepwise regression analysis made clear that response to amino acid density is very significant for body weight, FCR and breast yield. FCR is the parameter most affected by dietary ME. The affect of ME on body weight and breast yield is not as great as that of amino acid density. Similar exercises can be performed for mortality, eviscerated carcass yield, wing, thigh and drum yield.Once the biological responses have been clearly defined some basic economic calculations can be made. These basic calculations require knowledge of the input cost (feed costs), the biological response to those inputs and the value of the outputs (live bird prices, whole carcass prices or portions prices). The result is a value representing margin over feed cost for each possible scenario.

Flexibility in use

The model offers the user the flexibility to vary feed prices as well as prices of all potential products (live birds, carcasses etc). Once the feed price, product prices and product mix have been specified, the model will provide the user with an ME and digestible lysine level that will optimise margin over feed cost under their conditions. Dietary energy and amino acid levels recommended by BEEP can be compared to the user’s current levels. Rather than changing immediately to the levels the model is suggesting, it may be sensible to make smaller incremental changes in the direction the model suggests. This will give the producer the opportunity to evaluate the effectiveness of the changes. Figure 3 is an example of one of the outputs of the model. The graph shows that optimum margin is obtained at an ME level of approximately 3,020 kcal/kg and a digestible lysine level of 1.20%. Any possible combination of prices, product mixes and feed costs can be entered. For example, if the feed price from the scenario above was increased by 25% and all the product prices were reduced by 25% the ME and digestible lysine levels to optimise margins would be 3,050 kcal/kg and 1.14% respectively. The depicted scenario represents a producer selling deboned product. From the scenario above with feed prices of $280/t, if a producer was selling whole carcasses at $1.96/kg the optimal ME level would be close to 3,075 kcal/kg and the optimal digestible lysine level would be close to 1.10%. The lower recommended lysine levels and higher recommended energy levels are indicative of the product mix. With whole carcasses being the product, FCR becomes more important than white meat yield for example. This is evident in the model’s recommendations.

Optimum nutrient density

The BEEP model also has the capacity to conduct a parametric analysis to show how optimum energy and amino acid density changes as feed prices vary. And it is able to offer an indication of what would happen to both performance and margins if ME or amino acid levels change. All of these features allow the nutritionist not only to make the right decisions but also to understand the potential impact of wrong decisions. A tool such as BEEP makes it a lot easier to react appropriately when market conditions change. The ideal nutritional strategy is a moving target and feeding programs should be reviewed regularly to remain close to this target.