Regular and consistent results for higher economic efficiency

The enormous pressure on prices is forcing all organisations to improve their economic efficiency in a profound way. The world of livestock farming is not immune to this constraint, quite the contrary.

Whether it is to produce chicken meat, eggs or even pork, feed costs represent more than 50% of the production costs of the farm level. This is why it is essential to focus on feed efficiency. But in the food chain, livestock farming is not the only part involved. Production companies and slaughterhouses have their own constraints. Although a major focus is currently on energy costs and to find manpower, these companies also have to manage the fluctuations of livestock production at the group level. In fact, the number and weight of animals at the slaughterhouse is never what was planned at the time of setting up. Mortality on the one hand, but also the vagaries of breeding on growth performance are a source of deviation that penalises the slaughterhouse and the entire production chain.

Today, it is possible to improve the situation by action on both:

The economic resilience of farms via feed efficiency

The economic efficiency of production organisations through regularity and homogeneity of production

Feed efficiency for the economic resilience of farms

Feed efficiency is the main indicator of technical performance in poultry and pig production. With meat or egg prices at their highest, but not always compensating increases in feed prices, the feed conversion ratio becomes the first economic indicator to improve.

Some technical solutions aimed at lowering the cost of feed quickly show their limits. Performance or at least the feed consumption ratio must be maintained to continue to make the most of the high selling prices of products. Therefore, each time a new raw material is incorporated, or the safety margins for nutritional requirements are being lowered, a way of securing the results must be implemented. Feed additives based on essential oils formulated for performance have their place in this strategy, and for a modest investment (see previous article).

Another approach is to invest in a solution that will increase the yield of the feed into meat or eggs. In this situation, the target is to decrease the feed conversion ratio to lower the feed costs of production and/or to produce more for the same price. Here again, additives formulated with essential oils are more than relevant because of their affordable investment cost and particularly high return.

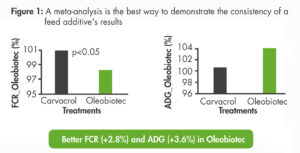

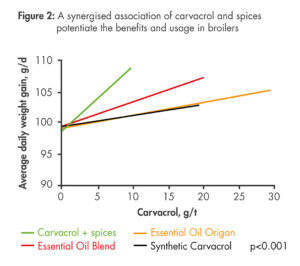

In the end, the success of the operation relies now on the regularity of the results obtained despite the various farming conditions. Selecting the right combination of actives with the right dosage for each, enabled Phodé to propose Oleobiotec Poultry, a solution that gives regular and consistent results in a variety of farm environments. The more complete and synergistic is the composition, the more effective is the product (Figure 2).

Regularity for an easier planning of the global production and more economic efficiency

On the scale of a production organisation, economic efficiency relies on an efficient planning: sending to slaughter the animals that correspond in number and quality to the needs of the slaughterhouses on a given day. Yet live animals do not lend themselves well to mathematical planning.

The product that will make all animals from the different farm attain the exact same weight on the exact same day is not yet available. However, Poultry fed Phodé’s solution Oleobiotec Poultry show higher and more regular average daily weight gain (Figures 1 and 2). The variations in performance from one batch to another are reduced, and so are the planning differences. By simply reducing the delays in the different farms, it is easy to gain one effective day of production which, depending on the situation, can be invested in a more secure sanitary vacuum or an increase in overall production: 1 day of production gained per cycle = 2% more annual production.

Supporting feed efficiency and production

This is why Oleobiotec Poultry is used on a farm scale to support feed efficiency and improve production homogeneity for everyday benefits for the overall production organisation:

More profitable batches for farmers: lower FCR

More homogeneous batches at the slaughterhouse: fewer downgrades for the farmer, better slaughter performance for the slaughterhouse

More consistent results from one batch to the next: fewer planning deviations for the production organisation

Everyone wins.