Sodium butyrate supplementation for poultry – coated or uncoated?

Products with different releasing time within the GI tract can have various biological responses based on where they release. Partially coated sodium butyrate can release sodium butyrate from the foregut until the hindgut and is a good overall option for all growth stages.

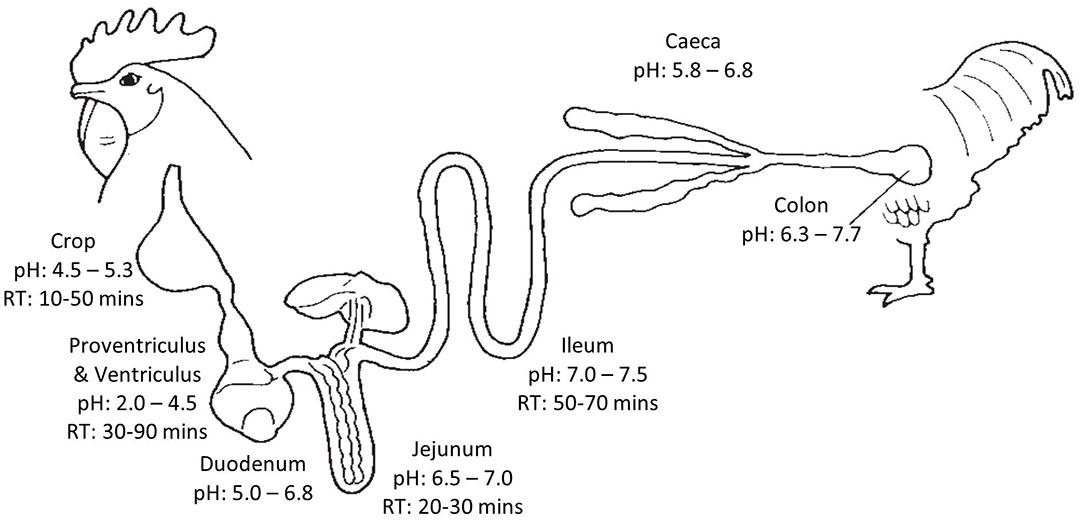

The gastrointestinal tract (GIT) of the chicken is relatively short compared to other production animals such as swine, dairy cows, beef cows, sheep, and goats. The relative pH and retention times (RT) of corresponding GIT positions can be seen in Figure 1. Butyric acid products have been widely used in the poultry industry and their positive effects are well documented. This article discusses the importance of product releasing site for uncoated and coated butyric acid products and the effects they bring to the animal.

Figure 1- Diagram of the digestive tract of chickens adapted from Gabriel (2006) and Ravrindran (2013).

The importance of product releasing site (coated? uncoated? butyrate salt? esters?)

The efficiency of sodium butyrate, calcium butyrate and tributyrin depends upon the pKa value of butyric acid and pH of the corresponding part of the digestive system. At a pH of 4.82, butyric acid remains in equilibrium between butyric acid, and butyrate and hydrogen ions. If the pH of a medium is less than the pKa value of butyric acid, most of the molecules of butyric acid remain un-dissociated. It is important to understand pKa because butyric acid and butyrate exerts different functions in the intestines, and it allows us to understand how butyrate salts or esters work in the body.

The fate of sodium butyrate

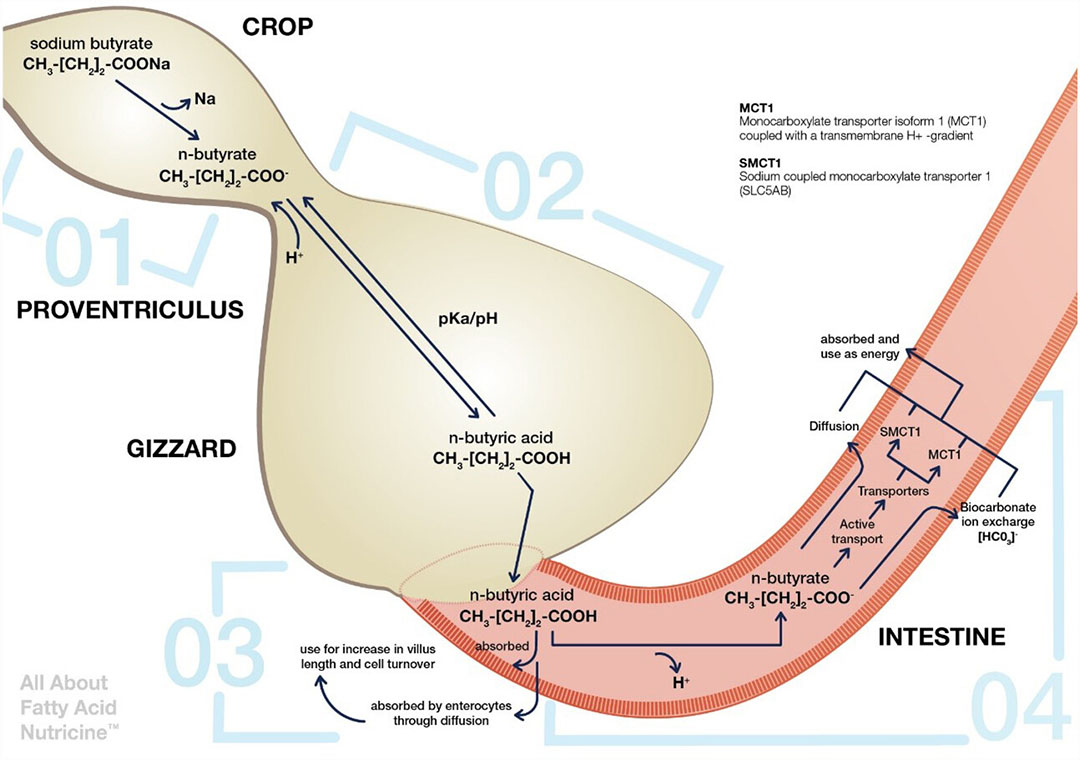

STAGE 1: Sodium butyrate dissolves and forms butyric acid after ingestion.

STAGE 1: Sodium butyrate dissolves and forms butyric acid after ingestion.

STAGE 2: As the crop, proventriculus, and gizzard has an acidic pH, it allows butyric acid to stay in its un-dissociated form. Butyric acid modulates MUC gene expression in goblet cells which improves the properties of the mucus layer thus improves the protection of the gizzard!

STAGE 3: When butyric acid enters the proximal small intestine, it will dissociate into butyrate and hydrogen ions. Here, butyric acid is readily absorbed by enterocytes via passive diffusion and used to increase villus length and cells turnover.

STAGE 4: However, due to the higher pH in this environment, butyric acid becomes dissociated into butyrate ions which can be absorbed as a source of energy as well, which require different methods for their absorption.

→ Via diffusion

→ Via HCO3- exchange method

→ Via active transport (MCT1 & SMCT1)

Nonetheless, butyric acid is the preferred source of energy for the enterocytes.

Figure 2 – Conversion of sodium butyrate to butyric acid in the bird’s intestine and its absorption. (Adapted from Ahsan et al., 2016)

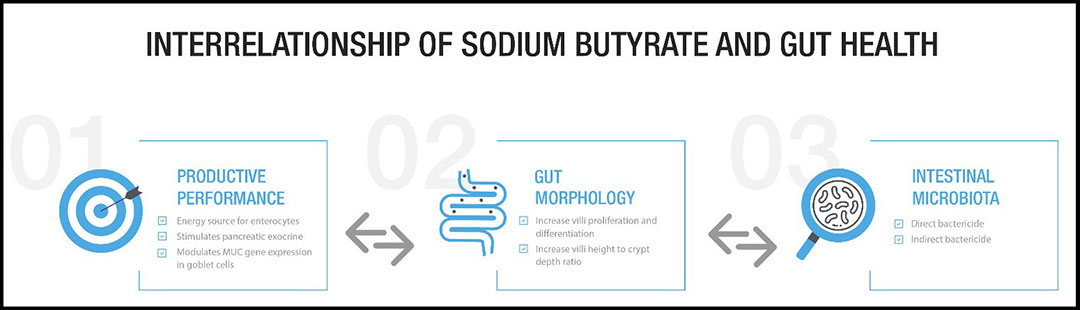

1. Productive Performance – Protection, Digestion & Absorption

Energy source for enterocytes: Increase villi length and density → Increase overall absorptive surface area → Increase BW gain and FCR

Stimulates pancreatic exocrine → increasing digestive enzymes secretion (amylase and lipase) → Digestion improved.

Modulates MUC gene expression in goblet cells → improves composition and properties of mucus layer and improves its protective function.

2. Gut Morphology

Increase villi proliferation and differentiation – improve intestinal integrity, prevents epithelia lesions, increase water and sodium absorption.

Increase villi height to crypt depth ratio

(1) Long villi

a. Increase absorptive cells.

(2) Shallow crypts

a. Slow turnover of secretory cells (less demand for new tissue) – efficient absorption of nutrients.

(3) Deep crypts

a. Rapid tissue turnover (high demand of new tissue;

b. Increase secretions into GIT, resulting in diarrhoea, decrease in disease resistance and decrease animal performance.

Uncoated sodium butyrate dissociates into ions (pKa is lower than pH of intestine) which cannot be readily absorbed via diffusion. Therefore, effects on improved gut morphology are limited to the upper part of the intestine.

Differences were observed at 21 days old broiler but not 42 days old (because intestine is already fully developed at an older age; Levy et al., 2015)

3. Intestinal Microbiota – Bactericidal Effects

Direct Bactericide – butyric acid can penetrate the lipid membrane and cause cell toxicity inhibits Salmonella and Clostridium perfringens and decreases Salmonella infection in different organs (crop, caecum, and liver)

(1) Butyric acid can down-regulate gene expression and invasion of some bacteria (i.e., Salmonella)

Indirect Bactericide– Modulates bacteria that favours an acidic environment and lactic acid producing bacteria (Lactobacilli and Bifidobacterium) by lowering pH of the intestine

(1) Increases competition for space and nutrients with pathogenic bacteria.

(2) Lactobacilli converts glucose to lactic acid which inhibits Salmonella spp. and E. coli.

So, should you choose coated sodium butyrate or uncoated sodium butyrate?

Well, it really depends on individual farm’s needs. When it comes to supplementing starter chicks, we recommend using uncoated sodium butyrate simply because the coating would burden the underdeveloped digestive system of young chicks. Furthermore, young chicks will benefit in the long run with improvement in gut morphology and integrity preparing them for growing well. Besides that, the early release allows for proventriculus and ventriculus protection against the acidic secretions and development of epithelial cells in the gut. When supplementing grower to finishers, layers, and breeders, we could opt for coated sodium butyrate the coating does not pose negative effects to their productivity.

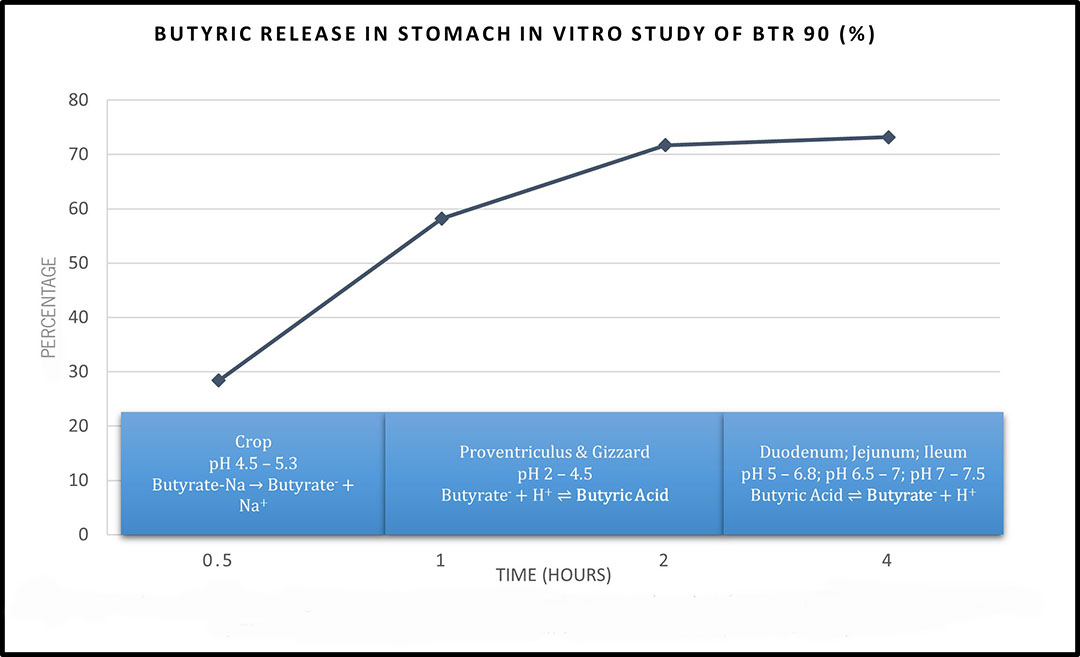

Switching between coated and uncoated sodium butyrate could be troublesome for producers and some prefer using just one additive throughout the bird’s life cycle. Thus, producers can choose BTR 90 (90% partially coated sodium butyrate) for all stages of bird production which is able to exert effects of butyric acid starting the proventriculus all through to the hindgut ensuring maximum effects of butyric acid within the gastrointestinal tract (Figure 3).

Figure 3 – In vitro study of releasing times of BTR 90 in the stomach compared against feed retention time (Bold text indicates favourable formation of the substance in the equilibrium) (Unpublished Data).

Looking at Figure 3, we can see that BTR 90 (partially coated sodium butyrate) is dissociated into butyrate and sodium ions starting in the crop (where pH is higher than pKa of butyric acid). In the proventriculus and gizzard, the low pH allows for butyric acid to remain in its undissociated form thus exerts antibacterial effects in the proventriculus and gizzard reducing the pathogen load of the animal. At the proximal duodenum, butyric acid is readily absorbed by enterocytes via passive diffusion and used to increase villus length and cells turnover thus improving intestinal integrity. Besides that, this allows for increase in beneficial acidophilic bacteria such as Lactobacillus and Bifidobacterium which increases competition for pathogenic bacteria and increases lactic acid production which inhibits Salmonella spp. and E. coli. As butyric acid travels along the way, it increasingly favours formation of butyrate and hydrogen ions (due to higher pH).

As the pH of jejunum and ileum exceeds pH 4.82, butyrate anions are increasingly formed and is absorbed through passive absorption, HCO3- exchange method and active transport (via MCT1 and SMCT1). Hence, the antibacterial ability in vivo is lost. Using a coated sodium butyrate or partially coated sodium butyrate, allows continuous release of butyrate in the small intestines. Although there may be small quantities of butyric acid continuously released from coated or partially coated sodium butyrate, the equilibrium still favours the formation of butyrate anions, therefore the antibacterial effects would be short lived. Butyrate anions formed would be absorbed and used as energy by the epithelial cells.

The benefits of having some butyric acid released earlier on in the digestive tract is proven by an internal study conducted to compare the effects of coated (30% sodium butyrate; 900g/t) vs partially coated sodium butyrate (BTR 90; 300g/t) on native meat birds from Day 8 to Day 67 and found that BTR 90 outperformed coated sodium butyrate at a much lower dosage (Figure 4). This shows that a continuous release of sodium butyrate throughout the gastrointestinal tract is more advantageous rather than targeted site release. Most studies emphasise on the effects of butyric acid in the hindgut, overlooking the foregut. However, this study has shown that upper gut release is indeed important and beneficial to the birds.

Figure 4 – Effects of BTR 90 VS 30% fully coated sodium butyrate on the feed conversion ratio (FCR) and average daily gain (ADG) of native meat birds. (Unpublished data, 2021)

New generation of sodium butyrate

Manuka Biotech, Malaysia, and our parent company, Singao, China carries a series of butyrate products including uncoated sodium butyrate products, coated sodium butyrate products, partially coated sodium butyrate and butyrin products. Furthermore, Singao has been the leading manufacturer of sodium butyrate related feed additive market in China for over 20 years.

Manuka Biotech, Malaysia, and our parent company, Singao, China carries a series of butyrate products including uncoated sodium butyrate products, coated sodium butyrate products, partially coated sodium butyrate and butyrin products. Furthermore, Singao has been the leading manufacturer of sodium butyrate related feed additive market in China for over 20 years.Our partially coated sodium butyrate, BTR 90 is made with our recently launched, new generation of sodium butyrate which are ball-shaped granules instead of the conventional rod-shaped granules. The uniform ball-shaped granules offer multiple benefits compared to the conventional rod-shaped granules which allowed us to achieve:

- High potency (90% sodium butyrate) but light to odourless.

- Lower inclusion rate (300g/t for poultry diet).

- Crystalline matrix with interwoven structure, a novel technology, enhanced coating ability to form slow-release products.

References available on request