Animal nutrition with high-quality pellets

As feed producers strive to optimise both efficiency and sustainability, the importance of consistently producing high-quality pellets becomes increasingly clear. This article explores the key factors behind effective pelleting, the impact on animal productivity and how lignin-based pelleting aids can support process optimisation.

Why pelleting matters

Pelleting is the process of compressing and shaping feed into dense, uniform pellets. This transformation offers a number of benefits across the feed production chain:

- Improved feed efficiency: Pellets increase the digestibility of nutrients, leading to more efficient nutrient absorption.

- Reduced feed wastage: Unlike mash feed, pellets generate fewer fines, reducing losses during feeding and transport.

- Enhanced handling and storage: Uniform pellet size improves flowability and reduces bulk volume, making storage and logistics easier.

- Improved feed safety: The thermal conditions during pelleting help reduce microbial contamination, including pathogens such as Salmonella.

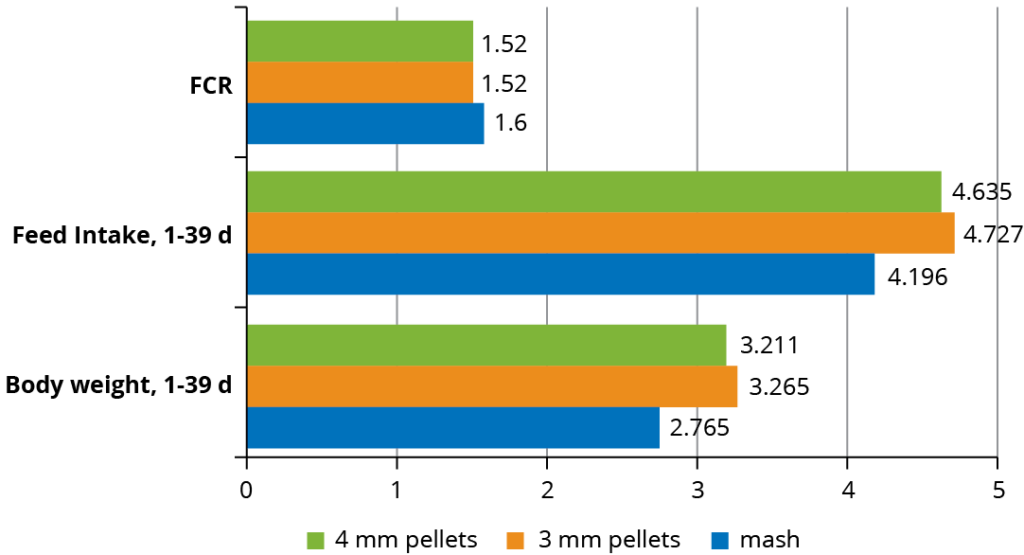

Figure 1 – Growth performance of Cobb 500 male broilers fed diets varying in feed form.

Impact on animal performance

Pellet quality has a direct influence on animal productivity. Research consistently shows that animals fed high-quality physical pellets experience improved growth, better feed conversion and enhanced overall health.

In a recent broiler trial, diets based on 3 mm and 4 mm pellets outperformed mash feed, showing significant improvements in feed intake, body weight gain, and feed conversion ratio (FCR) (Figure 1).

Additional benefits include:

- Better growth rates through improved nutrient density and intake

- Lower feed conversion ratio (FCR), i.e., less feed is needed per unit of weight gain

- Reduced feeding stress and aggression, particularly in intensive systems

- Improved gut health and immunity, supported by balanced contaminant-free diets

What makes a good pellet?

Producing durable, nutritionally intact pellets depends on a combination of formulation and processing factors:

- Ingredient quality and consistent fineness of grind: Affects surface area and binding potential

- Steam conditioning: Enhances starch gelatinisation and binding

- Die selection and pelleting equipment: Influences pellet shape, density and throughput

- Cooling and drying: Stabilises pellet structure and reduces moisture

As noted by researchers, these variables interact to define overall pellet durability and efficiency. Feed producers often work within tight margins, so small adjustments in formulation or processing can have significant economic benefits.

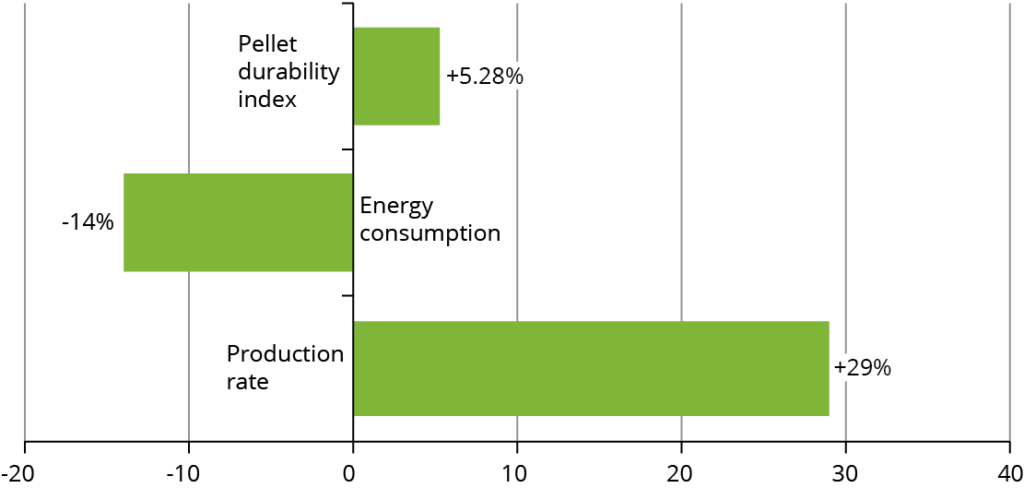

Figure 2 – Effect of a Lignin-based pelleting aid (average of 30 trials).

The role of pelleting aids

When working with challenging formulations – such as those high in minerals, fats or fibre – pelleting aids can make a measurable difference. These include binders and lubricants that support pellet cohesion and improve production throughput.

Lignosulfonates, derived from the wood pulping process, have long been used as effective, sustainable binders. These solutions help improve pellet quality, reduce fines and support efficient operation, especially when processing challenging feed formulations.

Proven benefits: Trial insights

A summary of 30 commercial pelleting trials conducted on pigs, poultry and horse diets using a lignin-based pelleting aid (Figure 2) demonstrated clear technical and economic benefits:

- a 29% increase in production rate

- a 14% reduction in energy consumption

- a 5.3% improvement in the Pellet Durability Index (PDI)

These results highlight the contribution of pelleting aids not only to feed quality but also to cost efficiency and sustainability in modern feed milling operations.

Sustainable solutions for feed production

Lignin-based pelleting aids are produced from renewable resources, aligning with the feed industry’s growing focus on environmental sustainability. Key benefits include:

- Resource efficiency: Durable pellets improve feed utilisation and reduce the environmental impact per unit of animal protein

- Reduced waste: Fewer fines mean less feed loss throughout the supply chain

- Sustainable sourcing: Lignosulfonates are derived from responsibly managed forestry operations

Pellet quality is more than a technical target — it’s a key driver of animal performance, operational efficiency and sustainability. By focusing on formulation, process optimisation and the strategic use of pelleting aids, feed producers can unlock significant value across their operations. With the right tools and insights, high-quality pellets are not just achievable — they’re economically and environmentally essential.