How to digitise a feed mill

The benefits of digitising continue to grow, but many companies have yet to take the plunge. Read on for inspiration and practical advice.

Digital transformation is something that’s making inroads in companies across all industries, and its implementation has intensified during the pandemic due to the efficiencies it provides.

Digitised vs Full digitisation

Feed companies in the developed world are all generally ‘digitised’ to the extent that they use feed formulation software. Full digitisation, however, refers to having a broad company-wide software platform that transforms a business in many ways.

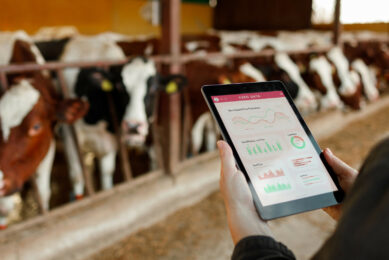

A digitisation platform, for example, allows company leaders and front-line staff access to real-time data and historical records for better current decision-making and projection of future trends.

It also interconnects various parts of a company for greater efficiencies. That is, with various departments (for example, sales, HR, product management, maintenance and so on) all connected, information flow is faster, everyone is up to date and errors are spotted more easily.

Digitisation also enables companies to efficiently interact with all parts of the value chain, which is increasingly required in the feed industry.

Need to better deal with data

Despite these critical advantages, many feed companies have not yet undergone digital transformation, and the number that have is hard to determine, says Casper Niesink, director for nutrition, formulation, animal modelling and digital services within Trouw Nutrition. It also, he says, depends on how you define ‘full digitalisation.’

“We do see an increase in the use of NIR desktop systems at feed mills, and also mobile devices to test raw materials that are entering the feed mill,” Niesink explains. “And this is already a from of digitalisation on its own. It comes with an increased need to better deal with the data that is generated with these devices. And here is where the next phase of digitalisation comes in: digitalising the data flow, making it visual and creating reports for example. This opens up the possibility that different stakeholders within the feed company can work with the same data and do this simultaneously.”

He adds that this digital feed data management makes it possible to make better strategic decisions because you can see trend lines for certain samples that you bought from the same supplier, for example looking at crude protein content variations.

In addition, Niesink says digitalisation is also very much about establishing connections among relevant data sets.

“Here we talk about connecting NIR data with the feed formulation software, for example,” he explains. “This allows us to formulate with the most accurate values (instead of updating them manually in the feed formulation software). But also the connection with NIR data and with a Life Cycle Assessment (LCA) calculator is a form of digitalisation. With this data connection, the feed miller can formulate on the basis of nutritional value, cost and environmental impact. These data connections are not always a standard aspect of feed mill operations.”

Identifying sustainable feed

Feed mills that use digital tools relating to LCA can also advise farmers which feed is more sustainable than others. This can be relevant for farmers who are part of a sustainability programme, says Niesink, for example from their dairy processor that buys their milk or the retailer that buys their meat.

In addition, feed companies, especially right now in the aftermath of the pandemic and with the war in Ukraine, need to keep their customers up-to-date, to the minute if possible, with price changes, changes in ingredient availability and other market fluctuations.

In general, says Niesink, managing logistical issues has become more complex with the pandemic. A number of labour strikes over the last few years have also presented challenges for the feed industry in Europe.

“This has forced feed millers to source their feed ingredients from more different regions and suppliers, increasing the need for overview of data and more need for sampling, to ensure the quality of unknown suppliers or new types of raw materials that you do not buy often,” he says.

Barriers to digitisation

There are several reasons why some feed companies haven’t yet started digital transformation.

They can, for example, be legitimately resistant to the idea based on past and current good company performance, that “we’ve always done it like this, we are doing a good job, we are making a profit and there are no complaints.” This attitude is tied in with a reluctance among company leaders to investigate the benefits that will come with digitising.

There is also resistance to digital transformation because of the required investment – not just the monetary cost but the cost in terms of staff time and resources.

However, while Niesink recognises that the costs of investment are always a consideration, he explains that “in general we can state that feed mills that don’t digitise will have higher costs. If you can digitise processes – and communication – among procurement, quality and assurance department and nutritionists within the same company, you can reduce huge amounts of time and labour costs, with exact savings depending on the feed mill and situation. In addition, as mentioned, digitalisation reduces manual errors and makes records more accurate. And this is what customers want.”

He adds that with the growing trend of precision feeding, feed mills need to have the accuracy in nutritional values to be able to formulate accurately, and the quality of input data is then key. If feed mills can’t live up to that in their formulations, they will simply lose their competitiveness, says Niesink.

Taking the plunge

The first step to start digitising is to start by working with an experienced partner to determine what you’d like to improve, where your biggest efficiency challenges lie, where you have made errors, etc.

Overall, processes that require manual labour and accuracy (around feed analysis and feed formulation) are excellent starting points.

The process will involve many questions. For example:,

Is reducing energy costs a top priority?

Are you located in a region where labour is hard to find or very expensive?

Does your feed mill have multiple locations (and are you using multiple NIR devices that you could connect, for example)?

Taking small steps

It mostly starts with looking at how to solve one issue, taking small steps at a time. For example, at those feed mills that have NIR in place, the next step is having the NIR data in one overview (dashboard) to better see trends or weak spots.

The next step could then be to add more data to the same platform, for example to see trend lines in mycotoxin levels from certain suppliers of raw materials.

A journey of 1000 miles starts with a single step, as the proverb goes, and this applies to the journey of digital transformation as well.