Innovation and productivity in feed manufacturing

Innovation in feed manufacturing is a process that requires a good economic and R&D management plan. Such a plan would be worthless if people included in the R&D activity were not creative and productive. Such individuals create the opportunity for ideas to happen with incredible speed. From experiences at Fôrtek some valuable advice could be compiled.

By Dejan Miladinovic, Norwegian University of Life Sciences (UMB), Fôrtek, Norway

Considering that innovation is a continuous process of discovery, learning and application of new technologies and techniques from numerous sources, many of the techniques and processes are interdependent. Technological capacity of a firm may also be influenced by external factors such as the R&D infrastructure and the functioning of the capital markets. For the feed industry, applied innovations are a focus for any R&D team. Applied innovation occurs when an advanced technology is applied in the production process and it is positively correlated with R&D intensity, research personnel and investment in related equipment.The Centre for Feed Technology – Fôrtek, in Norway and its employees have gained a lot of knowledge obtained by observation of, and working with, industrial R&D teams and employees for many years. From these experiences a few tips related to the process of productive idea execution within the research, and hence creation, of valuable product development could be compiled. All these tips are based on collected observations by working with the R&D personnel and are not based on conclusions, they are only suggestive.

Tip 1 – Do not hesitate

Indefinite planning and dreaming about the company’s new product will hardly bring the research opportunity and hence experimental execution. If this period is too long the R&D managers and entire R&D team can lose valuable time and pattern of the idea created by marketing team. A bias towards the R&D action can be found in many creative professionals that are bound with so much varied information found in different scientific publications or other sources. These professionals should challenge themselves to take the action sooner rather than later. The minute R&D professional start acting, the sooner valuable feedback will help refine the original idea. In this way, R&D professionals will be able to move forward with a more knowledgeable perspective.

Tip 2 – Take the blue-sky concept out of your head

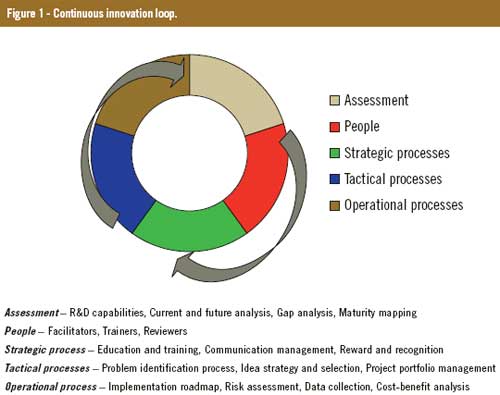

The good thing about a R&D concept is that it includes the team members within the continuous innovation loop (Figure 1). R&D individuals tend to keep their vast ideas in their head and it is very difficult to communicate with them about a simple research model. The downside of this is that such particular thinking brings action on a very low level. To avoid this kind of R&D paralysis the idea from the head should be put on paper immediately in an executable concept with the smaller performable series performed. Once the idea created on paper will be performed on a small scale, an insight will be obtained on how to employ some certain feed manufacturing technology and how the product development would be brought to the next level.

Tip 3 – Trials

In order to avoid a concept of trial and error, and before the R&D department will get to the final technological concept (Figure 2), some simulations can be performed with various software packages. Since the requirements for the feed industry equal the requirements of the food industry, some serious and modern approaches should be practised within the cheaper R&D advanced process-simulation environment. In this way, the R&D team will synthesise the knowledge obtained during the process-simulation and thereafter the idea can be refined, but also a new concept can be created or idea-development improved. If one of the simulated concepts satisfies the company’s requirements the pilot production can be executed with in-house equipment or the trial can be performed within the test installation of the developer. One thing that the entire R&D team should understand is to listen closely and learn from any single failure, which should not discourage them, but rather stimulate the team to do it again until the optimal product has been obtained.

Tip 4 – Project’s simplicity

During a project/product development a lot of ideas are created which usually expands the scope of the project. Most of the time this idea-expansion also cripples the project. The only remedy that can be suggested is to write down in the beginning a simple project statement and the goals with the end-result that should be expected. In the case that the R&D team has collaborators from other industries or equipment suppliers, the R&D manager has to make sure that there is agreement about the objective and that the entire agreed concept is revisited regularly. Remember, when scope starts crippling the research, you will notice it very fast.

Tip 5 – Work on your R&D project every day

Do not cripple you brain and creativity by forcing yourself to get done with the project as soon as possible. The best R&D and hence product development is done in small bites. The stimulus given to your brain by creative juices will start to flow more freely if you use only a half of your working day directly involved in the R&D project. For the R&D process it is not about how much you do it, but how often you do it. It is brain exercise that counts.

Tip 6 – Break long-term projects into smaller chunks

In order to manage all the expectations and to stay motivated for year-long or even longer endeavours the R&D personnel should try to break each project into smaller chunks that will take only a few weeks to complete. In that way the R&D manager can ensure that all the employees will stay sharp and everyone will feel that the project is more manageable. By the end of each project chunk some incremental small rewards should be provided in order to keep the team members enthused about the project. Even if there is a very long way to go it is very important to pause, to take stock of what has been accomplished and what is to be done. The creation of this momentum is very important for long term projects that require serious creativity and technological knowledge.

Tip 7 – Meetings only for a reason

Sometimes meetings can actually be a productivity drain for R&D. Anyhow, in the case that people must meet, the R&D leader should ensure that everyone who will be attending the meeting knows what needs to be accomplished from the outset. In the case that people that do not help out in achieving the R&D objective are present, the R&D manager should find a nice way to tell them that they can leave. A suggestion would be that R&D managers will ask in the beginning of the meeting a simple question such as: ”Do we all know why we are here?” or “Does everyone need to be here?” In order to trim the running time of R&D meetings, a standing meeting would be as convenient and as productive as long seated meetings.

Tip 8 – Be able to accept a no for some ideas

As R&D manager saying no to some ideas is the essential part of doing the job. Creative energy is not finite and therefore saying no is the essential part of the productivity equation. When the R&D department is in execution mode, please keep in mind that unexpected opportunities also would mean distraction from the work at hand.

Tip 9 – R&D rules of productivity are made to be broken sometimes

By developing routines during the R&D it should be followed only if they are working. Sometimes big feed millers and their R&D departments tend to follow up the rules set many years ago when lots of things were very different. Suggestion is that if forward motion has become impossible with your current routine, you should try something else. Read the scientific publications or publications from applied journals and bring in a new decision or create new routines. Breaking non-working habits offers a new perspective and helps the R&D team to recharge and head back to the fray.