All you need to know about compliancy in feed production

In the lively world of the feed industry, keeping everything in line with internal quality standards and regulations isn’t just a checkbox exercise—it’s a big deal. It affects the safety, quality, and sustainability of the animal feed we provide. Compliancy in the feed industry covers a range of areas, including where ingredients come from, how products are made, and the paperwork that comes with it. Luckily, modern software is stepping up to make life easier for feed manufacturers.

Ingredient compliancy: The safety net for feed production

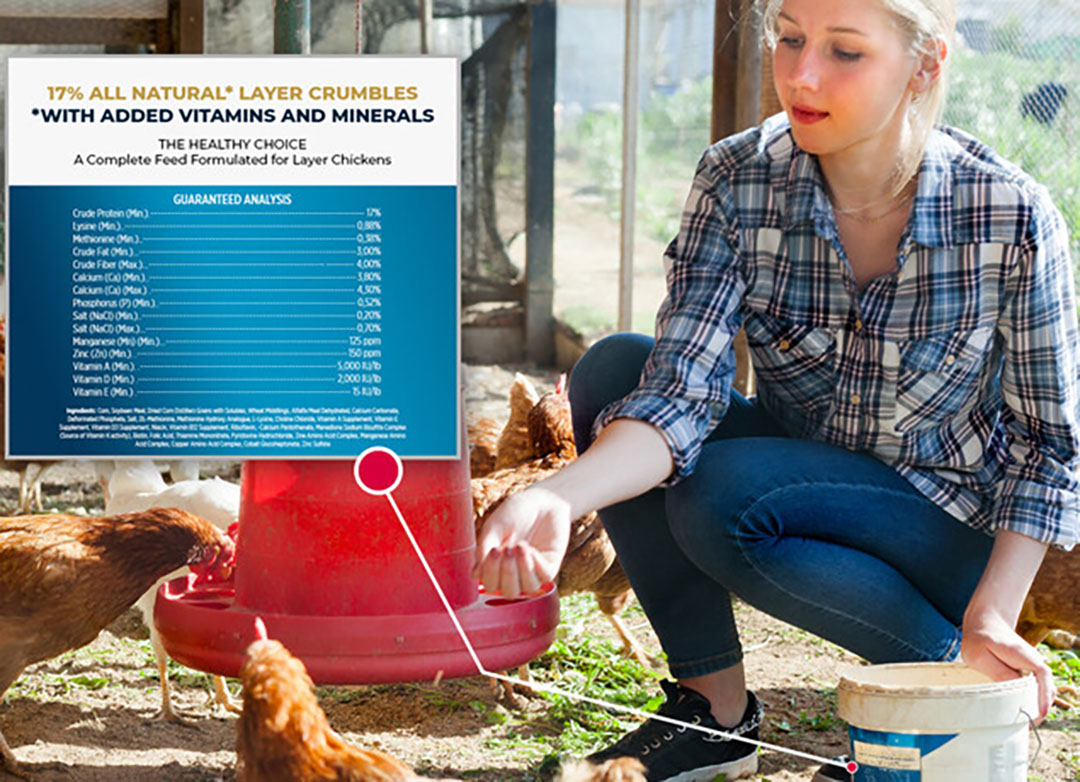

The heart of making high quality animal feed lies in getting the right ingredients. Ingredient compliancy is the key to ensuring the safety and quality of the feed. Knowing where each raw material comes from is crucial. In case of incidents, knowing the journey raw materials have made, ‘from farm to fork’, is key in the traceability of your entire supply chain.

This is where software becomes a game-changer. The right tools, such as the software solutions at Bestmix Software help manufacturers track raw materials seamlessly. It integrates with different data sources of suppliers, transporters, and warehouses, making sure the tracking process is consistent and accurate from purchase to production. Monitoring compliance becomes a breeze, with the software flagging any issues that go against the rules, or against the internal quality standards that are set. This not only keeps everything in line but also ensures a smooth production process without interruptions caused by inferior raw material batches.

The Bestmix Identification tool in the software suite takes it a step further. In situations where identification of raw materials is either a difficult, or a risk full undertaking due to the nature of the products, this tool makes sure the right product is used in production. With cutting edge technology, and without opening the packaging, operators on the factory floor receive confirmation about the goods received.

Product compliancy: Crafting feed with precision

As we move along the production process, the focus shifts to making sure the final product meets all requirements. Nutritional standards, commercial agreements, technological limitations and legal restrictions all influence the overall quality of the feed we produce. Many aspects formulators and nutritionists have to continuously pay attention to. To unburden you in this process, Bestmix Recipe Management allows you to define compliance frameworks. In every step of the process, from product design, to the creation of the final product, these frameworks are your insurance policy, your automated validation process that no product will leave the factory that does not meet the quality standards you have set.

As a second level of quality control, the 4-eyes principle can be enforced for the creation of new products as well. Via approval roles, different people from different departments (quality, product management, production, legal, …) can be assigned with the task to really approve new products. Again this ensures, that despite many automated controls, people still can play their role in making sure only the right product is shipped to your customers.

Document compliancy: Simplifying labelling and paperwork

While managing paperwork might not be the highlight of our work in the feed industry, there’s no denying its crucial role. The real value of our industry goes beyond the stacks of documents, and that’s where investing in time-saving software solutions becomes a game-changer for efficiency.

Let’s talk about Bestmix SpecTrack – it’s not just another online platform; it’s a game-changer for procurement in the feed industry. Imagine a world where communication between suppliers and manufacturers is seamless, and all the vital info about raw materials is just a click away. We’re talking detailed specs, manufacturers’ needs, assessments of production facilities, and certifications – all at your fingertips. Thanks to simple notifications, both sides stay in the loop, ensuring a supply chain that runs like a well-oiled machine.

Now, let’s dive into the jungle of rules and regulations, especially when it comes to finished products. Crafting compliant labels can feel like navigating a maze, eating up time and energy. That’s where a trustworthy partner steps in, guiding you through the entire process and freeing you up to focus on what really matters – the core of your business.

Picture this: user-friendly tools that effortlessly whip up accurate content, paired with design options that make your life easier. It’s like having the ultimate toolbox for tackling the complex world of document generation. And here’s the cherry on top – we’ve got your back when it comes to compliance. We’ve got the EU regulations, the US and Canada compendiums – everything you need to breeze through the process. With us, you can rely on 100% support.

Trusted guide

In conclusion, following the rules in the feed industry isn’t just a hassle—it’s a must for keeping animals healthy and happy. Modern software, like what Bestmix offers, is like a trusted guide in the sea of regulations. It helps track materials, formulate precise products, and streamline paperwork, giving feed manufacturers the power to not just meet but exceed compliancy standards in this ever-changing industry.