“The difference between a feed mill and a Skoda….”

May be you think “Harrij is getting crazy?” You may be right. But I want to discuss with you this issue. When you have a look at an average feed mill and compare this with a Skoda (or any other modern car) I see a lot of differences.

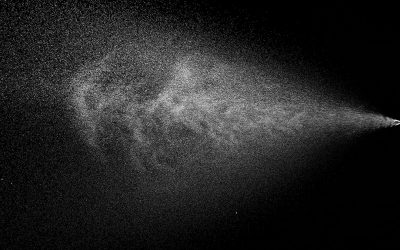

The first thing I see is that there is more technology in a car than in an average feed mill. Let me explain this. When you buy a new car you get park distance control in it and in the better (more expensive) ones a parking assistant which is parking the car fully automatically. Maybe there is a camera in the bumper. When you drive in a curve your lights are following the lane. Your cruise-control is controlling you as a driver. And a fully automatic board computer is telling you everything about the status of the driving process. Also the windows can be closed from the driver’s seat. A lot of technologies which could be perfect used in the feed mill to make feed, with less costs, and maybe higher, but surely better predictable quality. Technologies such as Vision (cameras), Sensors and Process Automation give a lot of opportunities for improvement.

Energy control

Another thing is the energy-control in the car. Every minute you drive you see what the energy use of the car is on your dashboard. Car producers are making extensive investments to produce cars which are using less energy. Energy and carbon are number one on the innovation agenda for the car industry.

Let us look at the feed mill again. If we now how much energy we use than it is on the level of the complete mill. You just take a look at the bill of the energy company. But we don’t now for instance what the effect is of the use of the expander in the process. Or even more complex; what the effect is of the use of ingredient A versus B on the use of energy in the production process. We just don’t use the technology which is available to control the energy we are using.I also have doubts if we are using the technology for consuming less energy in the process. In food we know that a lot of production units are using approximately 15-20% of their energy even when they are producing nothing…

Investing in a period of crisis

Yes, and now I hear you thinking. OK, but it is crisis. This technology is costing money – so not today, maybe tomorrow. But wouldn’t the crisis just be a good reason to think out-of-the-box and invest in new technologies? Look at companies like Apple who in heavy times invented the I-Pod. Or Philips/Sara Lee which in dark years invented the Senseo Coffeemaker and are getting a lot more money for each cup of coffee. But if you want to have an excuse not to use technology which is available you have one – the crisis.

I hope you don’t need this excuse and are doing the things you should be doing: Making the best feed for the best food in the world.