The better the pellet, the better the performance

Good quality pellets have several benefits: reduced waste, less segregation in the feed, improved palatability and shorter eating periods. Also animal performance and feed efficiency can benefit from pelleting the feed. But it is not always easy to make a good quality pellet.

Pelleting research in the sixties, which compared the feeding efficiency of mash, pellets, and reground pellets, found that with broilers growth response was lost when pellets were reground. Metabolisable energy was not affected by pelleting, but the diet fed as intact pellets had approximately 30% more calories of productive energy. It was speculated that this was the effect of less energy needed to eat pellets compared to mash. In a time trial, chicks fed mash spent about 103 minutes of a 12-hour day eating versus only 34 minutes with pellet-fed chicks. Also feed conversion (gain/feed) benefits from good pellet quality. Research and practical findings on commercial farms often indicated that on farms with good quality pellets, feed conversions were always better than when the feed was fed as mash or had a high percentage of fines.

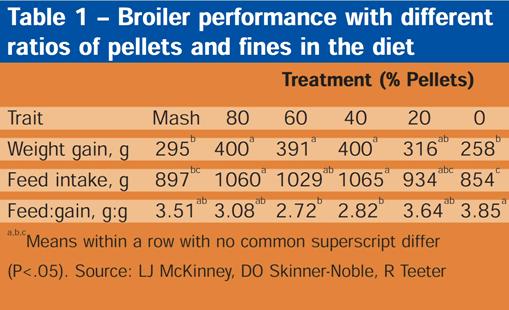

An experiment was conducted at Oklahoma Agricultural Experiment Station where broilers were reared to 42d of age, and then FCR was measured in a sample of the population from 43 to 50d of age in individual birdcages where they were fed a diet with different ratios of pellets and fines. The results can be found in Table 1. The data indicates that broiler growth and feed intake are enhanced when diets are fed as pellets compared to mash, and that pellet fines have deleterious effects on the rate and efficiency of gain. The researchers also concluded that if pelleted diets are comprised of less than 40% pellets, the benefits of pelleting are negated.

FCR improves in pigs

Trials showed improved feed conversion when pigs were fed pellets versus mash or poor quality pellets. Differences were found as high as 0.20 FCR for young pigs to 0.50 FCR for finishers to the advantage of pelleted feed. Researchers emphasised that unless a good quality pellet is produced, little if any benefit will be derived from pelleting.

Researchers at Kansas State University concluded that an important benefit of using pelleted feed in sows is increased digestibility of dry matter, nitrogen and gross energy. As a result, total output of dry matter and nitrogen as manure are decreased and the potential impact of a pig operation on the environment is reduced.

Nonetheless, the primary justification for a producer to use pelleted sow feed is to improve sow and litter performance during lactation and to give a better energy balance that would result in fewer difficulties with thin sows. The pelleting process does increase the cost of processing feed, so this investment must be offset by better litter performance and or body condition of the sow herd. If this cannot be achieved, the use of feed in a mash form is more appropriate.

Feeding dairy cows

For dairy cows it can be questioned if the concentrates they are fed should be in a pelleted form or not, since the bulk of their ration consists of roughage and TMR is the favourite feeding mode nowadays. However in the eighties researchers in the US evaluated different forms of feed for dairy cows, comparing pellets, coarse mix, crumbles, and meal. They found that cows consumed the pelleted feed more rapidly than the other forms of feed. This is important when eating time is limited, such as in milking parlour feeding. Here eating rate may be the most limiting effect on milk production. Although they did not test pellets with fines, the fact that pellets had an advantage over crumbles suggests fines would be detrimental.

For some other minor species of animals mash or fines in the feed is a matter of dying or staying alive. Ducks, for example, eat pellets but vary in their acceptance of mash or fines. Some will refuse to eat fines to the point of starvation and others will accept them with no negative effect. Rabbits do not eat fines at all. In contrary, fines may even cause health problems. Rabbits are very sensitive to respiratory problems. When for example dusty alfalfa pellets are fed, the dust is easily inhaled, which can cause respiration problems.

Aquaculture

In aquaculture, pellet quality is of utmost importance since any fines that are generated will be wasted when thrown into the water. Apart from that, it will also pollute the water, which has a detrimental effect on the oxygen supply and filter capacity. Trout and salmon for example, are quick eaters, but for shrimp, pellet quality goes beyond durability; because they are slow eaters and pellets must also have good water stability.

Fish farming is a rapidly growing way of supplying healthy food for mankind. However, for certain types of feed production and farming there are improvements to be done to avoid problems, which can sometimes be acute. Floating of the feed is such a problem. Oil leakage causing big lumps is another.

Floating of pellets has several causes. Small pellets with low weight tend to float on the surface especially if they have high fat content. With modern high speed feeding techniques air bubbles are formed when the pellet reach the water surface at high forces. The pellet is kept on the surface by the bubbles surrounding it. For the main part the floating problem is to overcome by regulating the density of the feed.

However, production technology does not solve all problems. It is possible to improve the wetting characteristics of the feed with help of optimised environmental friendly feed emulsifiers, which reduce the surface tension between pellet and water. There are different methods of applying the surfactant to the surface of the pellet. Normally it is done as a topcoat in the coating stage either mixed with the last oil or direct on the outer surface. The fatty pellets become more water friendly and the air bubbles are disrupted due to the lower surface tension. It is important to balance the system depending on the conditions, type of pellet, water temperature and so on. Oil leakage from the feed can cause severe problem both to the feed producer and fish farmer. There are several different techniques to solve this problem depending on the situation. One way to overcome this is to increase the absorption of the oil whereby a surfactant can help reduce the interfacial tension between the oil and the other ingredients. Better sinkability normally follows as a side effect.

Making good pellets

Although it is generally recognised that good pellet quality improves feeding efficiency, growth, and uniformity of animals, the level of quality is generally dictated by economics. However, feed with poor physical quality is always too expensive.

Many variables affect the pelleting process, including weather, meal moisture, and ingredient source. Evaluation of pelleting factors over a short period of time minimises some of these uncontrolled variables. Variables that cannot be eliminated (conditioning temperature, pelleting amperage) must at least be accounted for.

Pellet binders

Pellet binders (or pelleting performance enhancers) are products that are used to “bind”, “glue” or hold the various feed components together in order that they will maintain pellet integrity during subsequent operations after they are extruded from the pellet die.

Many products have been tested and a limited number have become widely used as binders in pelleted animal feeds. Current commercial animal feed binders can generally be classified under one of the following categories:

- Lignin based binders/lignosulfonates

- Hemi-cellulose binders

- Mineral binders (clays)

- Specialty binders (gums, starches, formulated products, etc.)

A number of the current binders in use are based on by-products from making wood and paper products. Some of the binders are mined minerals such as bentonite clays. In addition, there are numerous specialty binders that are based on certain types of products that are manufactured and/or selected or formulated for use as binders.

Effect of binders

At a test mill of LignoTech, USA the interaction between temperature, pellet binder and production rate was measured. During pelleting every five minutes samples were taken after the die to test for fines and pellet durability. Pellet quality clearly improved with temperature. Durability was relatively high at the peak temperature and low in the valley temperature.

Increasing temperature typically led to reduced amperage, at least until the choke point was reached. When the conditioning temperature rose above 85°C amperage began to increase. At this point the choke point was being approached. In a second run 1.25% lignin binder was mixed into the ration. At the start of this run there was a very evident improvement in pellet quality and reduction in amperage. Temperature was able to reach 90°C with little indication of a potential choke. Production rate increased more than 20% in the run with the pellet binder included without negative effects on pellet quality.

Temperature and fat

Lubrication by the pellet binder allowed feed to be conditioned to a higher temperature without choking. In another mill higher conditioning temperature was achieved by using fat (1%) as a lubricant. There was a positive lubrication response and power requirement per tonne was reduced by 10%. Temperature was increased continuously until the mill choked. Fat allowed the maximum conditioning temperature to be increased from 77°C to 82°C. Pellet durability improved with increasing temperature, but the additional conditioning achieved with fat was not enough to counter the negative effect fat had on pellet quality.

Emulsifiers

The Akzo Nobel group has an advanced surface chemistry centre located on the beautiful Swedish west coast. One of its specialties is emulsifier technology for feed production and aquaculture. At this centre of expertise a great deal of research on improving characteristics of fish feed with the help of emulsifier technology has been performed.

Emulsifiers not only have an important function in aquafeed, but can also improve the pellet quality and the pelleting process for feeds for terrestrial animals. Key in this process is managing moisture content when pelleting. This is made easier with the use of a derivative of the emulsifier known as Bredol. This additive retains precisely the right amount of moisture in the feed and at the same time helps to reduce energy costs. When water and fat are added separately to a feed mix they only penetrate the outer level of the feed particle and actively work against each other, as they cannot mix. This limits the extent of conditioning and reduces the stability of starching to bond one particle with another (Figure 1).

When water and fat are mixed together with Bredol, the properties of the latter are to combine both liquids in a stable emulsion after homogenisation. Bredol also removes surface tension and permits the emulsion to penetrate the feed particles. As a result the conditioning of the feed is improved and the surface of the particle is more able to bind with surrounding particles. . Due to this effect the pellets can travel faster and more smoothly through the die, which substantially reduces the electricity load on the pellet press.

Numerous trials have been conducted in Italy, where the additive was first tested, and later on in other countries. Akzo Nobel is now rolling out the concept through Europe, but emphasises that it is not simply adding a product to the mix. Sometimes as many as 20 or 30 trial runs have to be conducted before the right combination of product type and addition method is found. This also slows down the introduction process, because the use of Bredol has to be carefully monitored by Akzo Nobel specialists in the beginning.

Practical experience so far shows that the moisture content of the feed is in better balance and is lifted by about one percent. The second effect is that power consumption of the pellet press is reduced. At the same time a 10% reduction in power consumption results in a 15-20% increase in pelleting capacity.

Ingredient’s effect

Corn/soy rations are difficult to produce good quality pellets, but adding wheat can help to improve pellet quality. Wheat is known to be an ingredient that has positive binding properties. The glutenous nature of wheat makes it an excellent pelleting aid. Ten percent wheat in a formula will often enhance pellet durability, particularly in rations with little other natural binders. By-products such as gluten feed and distillers’ grains are low in carbohydrate, which can bind pellets. For this function, hard wheat is required.

In a commercial trial to compare the effectiveness of lignosulfonate versus wheat formulated into a corn/soy ration showed that inclusion of 1.25% lignosulfonate was equivalent to about 18% wheat. Temperature was again a positive factor in pellet quality.

In conclusion

There are many reasons used to justify the pelleting process. These include:

- Improved animal performance

- Decreased feed wastage

- Reduced selective feeding

- Improved bulk density

- Better material handling characteristics

- Destruction of deleterious organisms

- Customer expectations

- Feed dust/disease control

- Conditioning temperature is a strong factor for improving the quality of pellets comprised primarily of grain, especially corn/soy.

Fat is a strong lubricant but is harmful to pellet quality. Maximising steam addition and minimising fat added at the mixer are two steps that can improve quality at a relatively low cost per ton. Formulation changes that can be used to further improve quality include the use of a binder, surfactant or addition of wheat. Production rate has little effect and should be maximised.

Combining results from several trials, it is possible to predict how the various factors would affect quality of corn/soy pellets relative to one another. The predicted responses are listed in Table 2, starting from a base durability of 70. These estimates indicated that temperature should be maximized and fat should be minimised. Equipment problems sometimes restrict the mill’s ability to consistently maintain a high conditioning temperature. Pellet binders can improve pellet quality and are not dependent on temperature for activation; they can effectively reduce fines during problem situations. l

Reference:

E.C. Baudon and J.D. Hancock. Pelleted diets for lactating sows. Proceedings Swine Day 2003, L.J. McKinney, D.O. Skinner-Noble, and R.G. Teeter – Pellet quality effects on broiler growth and efficiency, 2001 Animal Science Research Report, Oklahoma State University, PJG Oostenbach, Akzo Nobel, The Netherlands, personal communication, T. S. Winowiski, LignoTech USA, Inc. – ‘Pellet quality in animal feeds’ and ‘Factors that affect pellet quality and trouble-shooting the pelleting process.’ www.asasea.com