Improved efficiency with protected amino acids

More efficient ruminant production systems often start with taking a critical look at diets and their nutritional contents. Choosing rumen-protected amino acids will help to increase protein efficiency, reduce losses and maximise dairy herd profitability.

Today, the dairy sector is facing several challenges; the increase in feed raw material prices, the high volatility of agri-food products of livestock origin, a decline in meat and milk consumption and, the public view that the dairy sector has a big impact on global warming. At the same time, ruminants are experts in converting low quality roughage or by-products that are not suitable for human consumption into high quality animal protein, contributing substantially to the high demand for animal protein in human diets. We will need to increase the rate of food production to meet the needs of a growing population and for that, farming practices need to become more efficient and sustainable. There is a major opportunity for ruminants to produce more efficiently thanks to better protein efficiency and as a result reduced nitrogen (N) excretion. Although feed-efficient ruminant production is a complex system, it often starts with better N efficiency1. Improvements in the efficiency of N conversion represent one of the biggest impacts on farm profitability2,3,4. At the same time, this allows us to reduce methane excretion per kilogram of milk produced.

Reducing nitrogen losses

Depending on the animal species, ration and management, between 5% and 45% of the N in vegetable proteins is converted into meat or milk. The other 55-95% is excreted (via urine or manure) and can be used as a source of nutrients for plant production5,6. However, the efficiency of re-conversion of the N into plant protein is limited; only a maximum of 60% of the N applied to the soil can be converted to vegetable protein and the rest will be lost. This is especially important when we consider that the estimated overall amount of N excreted by animals is comparable with the annual consumption of N fertilisers, if not higher. Strategies to reduce losses and improve the efficiency of ruminant production systems rely on an optimal supply of rumen degradable N and optimal efficiency of utilisation of absorbed amino acids (AAs)7. Generally, in ruminants the observed efficiency of conversion between N consumed and N deposited into protein varies between 20 and 32%, but the maximum theoretical efficiency should be between 40 and 45%8,9,7. A practical objective would be to achieve around 40% conversion, and this goal can be reached by formulating for low crude protein (CP) and balancing for AAs.

Using protected amino acids

Over the last few years, tremendous research efforts have been made to refine the protein requirements of dairy cows. Our growing understanding of cow requirements has led to recognising 2 sets of protein requirements: rumen degradable protein (RDP), and rumen undegradable protein (RUP). Metabolically the cow, of course, has specific requirements for individual AAs, rather than metabolizable protein (MP). Together, the complex microbial metabolic activity in the rumen and processes in the intestines make the study of N metabolism in ruminants more challenging than in the case of non-ruminants. AAs are the building blocks of milk and body proteins and they are considered to be one of the most important nutrients in dairy cow nutrition. Many of these AAs need to be supplemented in the diet, because they can’t be synthesized quickly enough to meet the requirements of producing cows. Therefore, these amino acids are known as essential AAs. Inadequate supply of essential AAs can limit milk and milk protein yield. The essential AAs that are present in MP in the smallest supply relative to the cow’s requirements is referred to as limiting AAs. Methionine (Met) and lysine (Lys) have been recognised as the first limiting AAs for lactating dairy cows under most feeding practices. This is fundamentally true because feed proteins have lower concentrations of Met and Lys when compared to their concentrations in milk and microbial protein. Mid-range crude protein diets in Europe are not able to meet Met or Lys needs with the use of dietary feed ingredients, so the use of rumen protected (RP) supplements is required. Different technologies have been developed to protect Met and Lys from microbial degradation, allowing the RP-AA to pass to the abomasum and small intestine where they are absorbed. These protected forms help to formulate feeds more precisely.

Keeping milk yields high

The benefits of Lys and Met balancing with RP-Met and RP-Lys for milk production and milk protein yield are well understood. Recent research has demonstrated benefits for the transition period, gene expression, reproduction role as well as product marketability due to higher levels of milk casein, which increases cheese efficiency at an industrial scale. It is remarkable that Met and Lys work in concert: both AAs are necessary in ruminant diets for the most precise feeding to achieve the maximum production performance without overfeeding protein. Met and Lys supplies are better predictors of both milk production and milk protein yield than the supply of MP. This is because when one of the AAs is limiting, this effectively causes an oversupply of all other AAs to the cow. When the missing limiting AA is provided, a new molecule of milk protein can be synthesized. Therefore, the surplus of other AAs will decrease, and the utilisation efficiency of MP will be improved. When dairy nutritionists rely only on the amount of MP available, with no consideration for limiting AAs, the actual milk yield will (in almost all cases) be lower than expected. This clearly indicates that, although the supply of total MP might be adequate, the balance of the available AAs can be incorrect, which limits milk production. It is widely accepted that, by formulating with individual AAs, the improvement in MP utilisation efficiency will provide the dairy nutritionist with an opportunity to formulate diets with lower CP content without compromising the yield of milk and milk components.

Using a LCA assessment

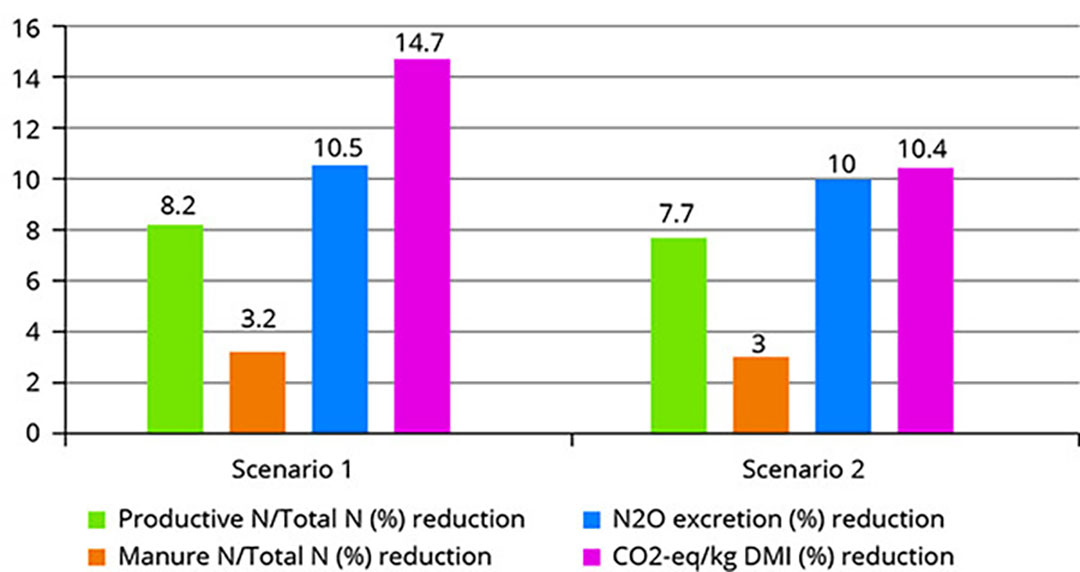

However, it is important to accurately predict the exact amount of metabolizable Met or Lys that can be used by the individual cow to reach this level of precision in our diets. Accurate precise measurement techniques are imperative for obtaining reliable experimental results in terms of N and AA utilisation. Knowing the rumen protection rate and the intestinal availability of the RP-AA supplement gives us the primary AA available to the host animal10. According to Kemin’s experience, when AA nutrition is implemented, applying the latest available nutritional knowledge and with the right rumen protected AA supplements (both, Met and Lys), better animal performance with improved nitrogen efficiency11 is observed. At Kemin, we took the United Nations 2030 Agenda for Sustainable Development as a guideline to determine our focus areas and responsibilities and based on this, we decided to focus on three areas combining all the sustainability actions: Healthy People, Healthy Planet and Healthy Business. These 3 lenses provide the framework used to measure the impact of the company’s efforts. All of them have both an internal and external scope. The internal scope – how can we improve our internal operations, sourcing, and production process? The external scope – how can our solutions (products and services) sustainably transform people’s life, animal welfare, the environment, and the operations of our customers? The global warming potential can be measured by using a Life Cycle Impact Assessment tool that evaluates the potential environmental impact of a product or activity throughout its life cycle. This is expressed in terms of carbon dioxide equivalents (CO2-eq), a unit used to compare the warming of a greenhouse gas with carbon dioxide which would have an equivalent impact. Kemin applied the LCA on different feed scenarios: a control diet without RP- AAs and 2 different diets with added RP-Met and RP-Lys (scenario 1 and 2). The control diet and scenario 2 contained soybean meal (Figure 1). Scenario 1 did not contain soybean meal. In both scenario 1 and 2, the crude protein level was reduced compared to the control diet but meeting the metabolisable protein (MP) needs for those animals. The LCA showed an improved nitrogen efficiency over 7%, reducing nitrous oxide excretion over 10% and saving over 10% CO2-eq excretion per kilo of dry matter for both feed scenarios, compared to the control diet. The feed costs did not increase by covering the Met and Lys needs with a RP-Met and a RP-Lys reducing the excess supply of MP12. This is how the AA formulation approach becomes critical to the ruminant sector, reducing N and CO2-eq excretion, and improving feed efficiency, enhancing the operating account per kilogram of milk or meat produced.

Figure 1 – Improved efficiency when using rumen protected amino acids in 2 feed scenarios with rumen protected AAs (in % reduction compared to control diet).

Conclusion

In conclusion, adopting the concept of balancing for individual AAs can bring endless opportunities for maximising dairy herd profitability. With continuous increases in feed prices and milk production costs, diet formulation with low crude protein content while balancing for AA, using rumen protected Met and Lys, can maximise MP utilisation, as well as dairy cow production and health. Additionally, balancing for the first 2 limiting AAs will decrease the overall N excretion to the environment, improving N and feed efficiency. All of this, by reducing the life cycle impact of daily formulations and improving animal health.

References 1-12 are available upon request.