The role of amino acids for maximum flexibility of dairy formulations

Over the last few years, tremendous effort and research have been made to refine the protein requirements of dairy cows. Our growing understanding led to the recognition of 2 key protein needs in dairy cows: rumen degradable protein (RDP) and rumen undegradable protein (RUP).

We know that intestinally available amino acids (AAs) are derived from microbial protein, RUP, and endogenous protein. These protein sources are called metabolisable proteins (MP). Metabolically, the cow has specific requirements for individual amino acids (AAs) rather than MP per se. In fact, AAs are the building blocks of milk and body proteins and are considered one of the most important nutrients in dairy cow nutrition.

It is crucial to know that many of these AAs need to be supplemented in diets because they simply can’t be synthesised enough to meet the requirements of producing cows. That’s why such AAs are known as ‘essential AAs’. The essential AA present in MP in the smallest supply relative to the cow’s requirements is called the ‘limiting AA’. And we’ve seen that an inadequate supply of these limiting AAs can affect milk, milk protein, and fat yield and can compromise other vital functions in the immune or reproductive system.

Methionine and Lysine supplementation as the answer

Methionine (Met) and lysine (Lys) have been recognised as the first limiting AAs for lactating dairy cows in most feeding practices. This is fundamentally true because feed proteins have lower concentrations of Met and Lys when compared to their concentrations in milk and microbial protein. Therefore, dairy rations should be formulated to provide MP with the AAs consistent and necessary for maintenance, growth, lactation, and reproduction.

We can improve Nitrogen (N) efficiency by maximising the MP produced and using high-quality RUP. Both strategies achieve a higher quality in the MP that can reach the small intestine. Rumen-protected amino acids (RP-AAs) are the most cost-effective way to provide limiting AAs. Even though these sources differ in the protection technology used (fat coating, pH sensitive coating, chemical protection, or analogs), we must know the true bioavailability of Met and Lys of all these supplements and choose the most metabolisable AAs for the price.

Mid-range crude protein (CP) diets cannot meet Met, or Lys needs using dietary feed ingredients. Therefore, the use of RP-Met and RP-Lys is needed. Remarkably, Met and Lys work in unison. Both AAs are necessary for our diets for the best, most precise feeding — achieving maximum production performance and adequate animal health without overfeeding protein.

The benefits of balancing AAs are endless if dairy nutritionists and producers are willing to adopt and apply the concept whenever possible. The improvements in terms of milk production, reproduction, and animal health will outweigh any additional costs.

Achieving all-round improved animal performance

From a nutritional research perspective in the dairy industry, there is greater interest in reducing N excretion and the possibility of reducing the CP in ruminant diets with a more precise formulation. There is a great opportunity for ruminants to produce more efficiently through increased protein utilisation and reduced N excretion, having a big — if not the biggest — impact on farm profitability and sustainability. In our experience at Kemin, when AA nutrition is implemented by applying the latest available nutritional knowledge together with the right RP-AA supplements (both Met and Lys), improved animal performance and feed efficiency are observed, leading to better absorption of N and phosphorous (P) and reduced carbon emissions.

AA nutrition for sustainability and flexible production efficiency

Applying the concept of AA nutrition allows for greater flexibility in our formulations and improved localisation of raw materials, leading to a reduction in costs and a lower carbon footprint per kilogramme of feed and milk produced. Rising feed prices, high volatility, and limited availability are the most constraining challenges facing dairy farm viability. As such, AA nutrition enables a flexible formulation when selecting or substituting different feed materials due to either price or availability. This flexibility allows us not to be too dependent on one or more raw materials when designing rations for dairy ruminants.

The aim of precision nutrition is to cover the animal’s nutritional requirements by avoiding as much as possible those nutrients that the animal cannot utilise. And all this while being able to use numerous raw materials without being overly dependent on any one of them. In addition to being efficient, this will allow us to cope with situations of limited availability of raw materials or excessive volatility or inflation. And when applying the concept of precision nutrition to protein, we must cover the needs of ruminal N, the MP supply, and the requirements of limiting AA, with the protein feeds available and at the lowest possible cost that allows us to obtain an adequate income over feed cost (IOFC).

Results made visible

You might ask how this is possible. It is not in our interest to simplify the AA formulation exercise, but let’s propose a diet for a dairy cow farm producing an average of 32 kg of milk with 3.9% milk fat, 3.5% milk protein, 150 days in milk, and a target intake of 22 kg of dry matter. We will call this diet Scenario 1. This diet includes 2 main protein feeds: soybean meal and rapeseed meal.

And now, we will formulate 2 other scenarios in which we have limitations of one of these sources: Scenario 2, with rapeseed but without soybean meal, and Scenario 3, with soybean but without rapeseed meal.

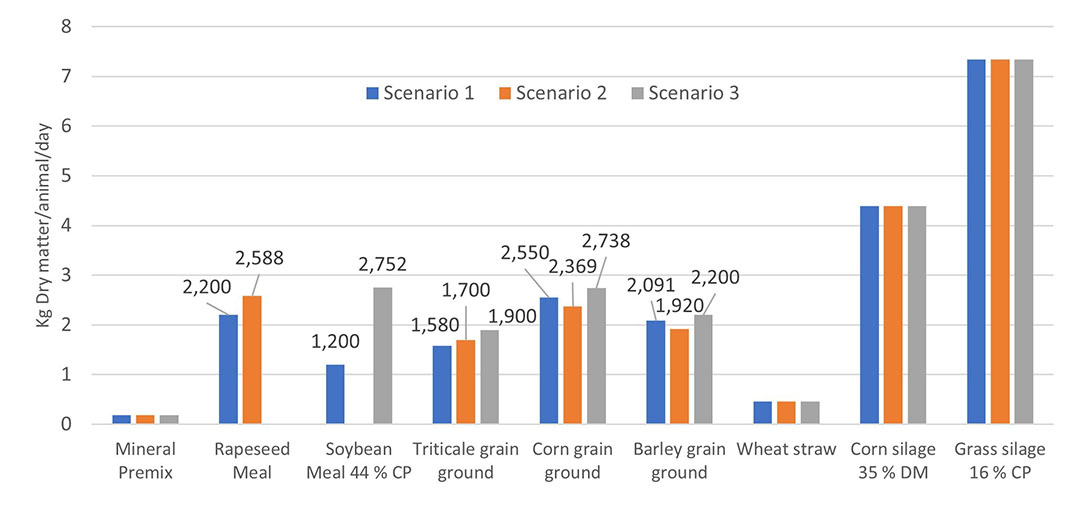

Figure 1 describes the ingredients used for the 3 diets formulation. The forage used and the mineral and vitamin content of the three rations are the same for all 3 scenarios.

Figure 1 – Ingredients (kg DM/head/day) of three formulation scenarios. Scenario 2 is formulated without soybean meal and with 8 of Kessent Me and 35 g of LysiGEM. Scenario 3 is formulated without rapeseed meal and with 11 g of Kessent Me and 19 g of LysiGEM.

These 3 diets (for scenarios 1, 2, and 3) are formulated to cover the nutritional requirements based on the model CNCPS 6.55 and were iso energetics (Table 1). But Scenarios 2 and 3 also meet limiting amino acid requirements using Kessent Me (RP-Met with 80% bioavailability, Kemin Animal Nutrition and Health, Belgium). and LysiGEM (RP-Lys with 70% bioavailability, Kemin Animal Nutrition and Health, Belgium). In Scenario 1, the diet doesn’t meet Met and Lys requirements (90 and 93%, respectively), so we are not maximising the protein efficiency and all the benefits that can be found in the scientific literature widely addressed. This formulation exercise that we have done with only 2 protein concentrates will be enhanced as more raw materials become available for our formulation.

The future of cow nutrition

In a nutshell, Kemin’s formulation with RP-AAs allows a better allocation of available raw materials, improving our formulation flexibility — sometimes even at a lower cost. We do this by improving the farm IOFC, reducing the cost per liter of milk produced, and taking advantage of the benefits of AA nutrition, as we have mentioned.

Should you wish to learn more about the benefits of flexible dairy formulations, view our references, and read about the formulated diets, please contact us via email, or visit us here.