Best use of local feedstuffs and co-products

In Canada there is a new ‘significant’ dataset for raw and processed crops as well as some co-products in order to be able to fully characterise the feed ingredients in terms of their chemical composition and nutritional value.

The global feed industry – and livestock producers – are well aware that using local crops and local co-products from food production, especially co-products that cannot be made edible for humans, provides benefits on many fronts. It’s obviously more sustainable to use local feedstuffs compared to transporting materials from afar, and co-product use has much less environmental impact compared to virgin crop use, even locally. These feed strategies also reduce cost (along with also cutting supply chain risks related to potential disruptions and foreign animal diseases).

3 biggest issues facing the feed industry

Reducing feed costs, advancing sustainability and addressing the need to support better gut health across all livestock species are the 3 biggest issues facing the feed industry right now, according to Dr Martin Nyachoti, professor at the University of Manitoba in Canada. In May 2023, he gave a presentation on how feed costs and sustainability can be addressed through better energy and nutrient utilisation at the annual conference of the Animal Nutrition Association of Canada.

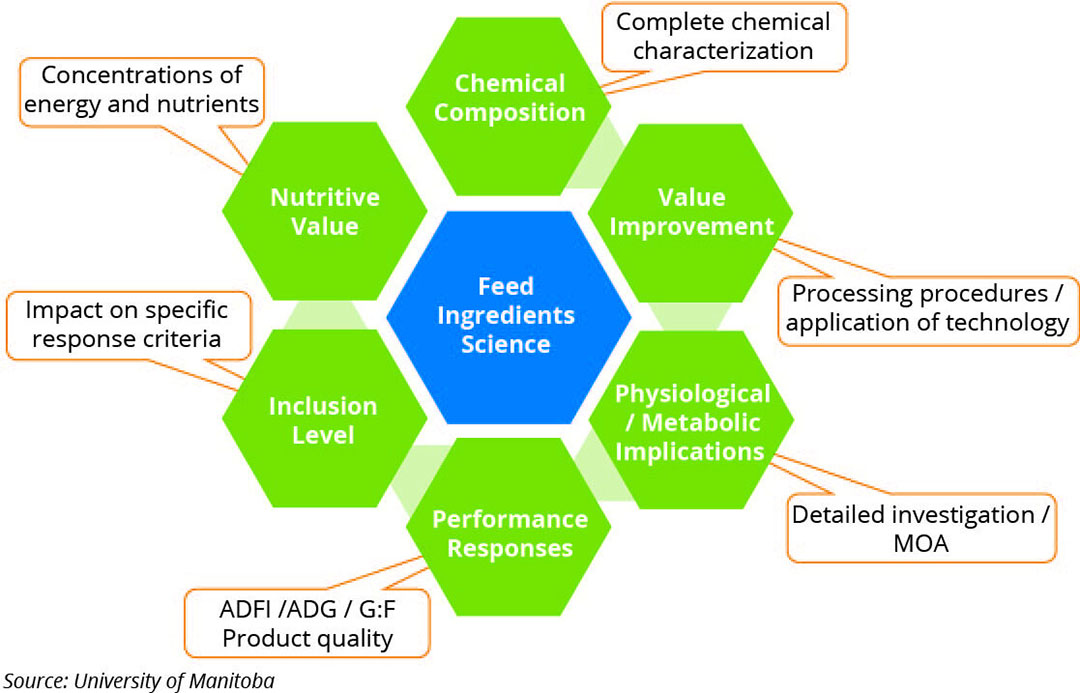

Figure 1 – Optimising the use of co-products in monogastric feeds must include analysis of these values, according to Dr Martin Nyachoti.

It all begins with data

“To gain the full benefits of using locally-produced feedstuffs and co-products,” says Nyachoti, “they must be fully characterised in terms of their chemical composition and nutritional value. In some cases, this characterisation must be done specifically for poultry and pigs and the different production classes in each, such as gestating sows, finishing pigs, broilers versus layers and so on.”

Because energy, protein and phosphorus are the 3 most expensive components in poultry and pig diets and the nitrogen (in protein) and phosphorus in pig waste are of particular environmental concern, it’s logical that any such efforts are directed at these components to meaningfully impact feed cost and mitigate the environmental footprint associated with livestock production.

Dr Nyachoti is excited to share the fact that “here in Canada, there’s been a concerted effort in the recent past to characterise established as well as novel feedstuffs in terms of their nutritive values and to examine the role of technology and processing techniques in enhancing energy and nutrient utilisation.” This has been done at various educational institutions, including the University of Manitoba and the Canadian Feed Research Centre at the University of Saskatchewan.

Established feedstuffs include soybean meal (SBM), canola meal (CM) and corn distillers dried grains with solubles (DDGS), a coproduct of the burgeoning North American ethanol production industry.

US studies

There has also of course been research into these areas within the USA. For example, Dr Gerald Shurson and Dr Pedro Urriola of the University of Minesota, in the context of pig feed, noted in a 2022 paper that extensive research has already been conducted to characterise the nutritional value of DDGS, identify its benefits and limitations.

However, they believe “similar investments in research are needed to develop methods for dynamically determining net energy and digestible amino acid and P concentrations in other major by-products used in pig diets to increase C, N, and P efficiency.” Shurson and Urriola also note there is “considerable interest in developing process technologies that upcycle nutrients from lower-value discarded by-products into feed ingredients.”

They explain that adoption of using more co-products in feed has been held back in the USA because of historical experiences of disease outbreaks linked to feeding uncooked ‘garbage’ to pigs. Regulatory change at the federal and state level, more education and more industry infrastructure encourage entrepreneurship in this area would help turn things around.

From a Western Canada perspective, Dr Nyachoti lists many commonly-available co-products, including maize DDGS, SBM, maize germ meal and gluten meal, CM and canola cake, camelina cake and meal, soybean hulls and dry-extruded meal, sunflower meal, oat groats and hulls, wheat bran, wheat DDGS and wheat middling, hemp meal and hulls, and pea screenings and hulls.

Dr Nyachoti stresses however, that “some of these ingredients are yet to be approved for use in livestock diets. Our research was designed to provide scientific data that may be used to facilitate such registration.”

For pig diets, one must also examine feed formulation strategies, feed additives such as enzymes and processing procedures

Analysis overview

Dr Nayachoti explains that optimising the use of co-products in monogastric feeds must include analysis of nutritive value, chemical composition and also the effects of dietary inclusion on performance/production efficiency at various inclusion levels. “For pig diets, one must also examine feed formulation strategies, feed additives such as enzymes and processing procedures,” he says, “including dehulling, particle size reduction/separation, heat treatment and so on.

…a characteristic feature of co-products is that they may contain a high fibre content, which may negatively affect their nutritive value for monogastric animals.

From some of the large amount of data now available in Canada, Dr Nyachoti looked at the analysis done by several research teams for some meals, seed and hulls, and notes that the NDF value (total plant fibre) varies greatly. It’s about 8% for SBM and about 23 for CM, around 30% for hemp seed, hemp meal and camelina cake (CC), about 42% for flaxseed meal and 57% for hemp hulls.

However, products that provide good levels of net energy for growing pigs ranges from 2.09 for SBM to 2.36 for dried extruded expelled SBM, with CM, HH and CC in between.

“It is important to note,” says Dr Nyachoti, “that a characteristic feature of co-products is that they may contain a high fibre content, which may negatively affect their nutritive value for monogastric animals. Use of technologies such as fibre-degrading enzymes have been shown to enhance nutrient utilisation when feeding diets containing high fibre ingredients such as canola meal and wheat co-products (e.g., wheat bran and middings).”

Also, different ways of further processing can go a long way towards removing the limitations of various feedstuffs.

Processing: Cost vs Gains

While various processing methods can enhance the nutritive value of co-products, research continues into the cost of these processes versus the gains in pig performance and profits, perhaps due to higher feed costs versus factors such as weight gain and better gut health that result.

Some processes are more costly than others (in terms of things such as energy intensity, specialised equipment etc.) and some have more effect or better effects on feedstuffs (in terms of boosting digestibility and so on). One positive note is that the more volume of a local feedstuff that can be processed for feed, the more the cost comes down.

Looking at some examples in pigs, extrusion generally improves energy and nutrient digestibility, dehulling increases energy and nutrient digestibility and growth responses, particle size reduction improves energy and nutrient utilisation and fermentation increases the nutritive value.

Remembering that these are novel co-products yet to be approved in feed, Dr Nyachoti notes however, that “in hemp, it’s been found by colleagues here in Canada that net energy contents of raw hull and extruded hemp hull were not different. Extrusion also does not affect the standardised total tract digestibility of P in hemp hull. I and my colleagues found that tail-end dehulling of canola meal improves apparent and standardised total tract digestibility of P in growing pigs.”

…great opportunities in the use of enzyme technology and processing procedures to enhance nutritive value and minimise variability

Moving forward

Dr Nyachoti and his colleagues believe that research into the nutritive value of novel co-products is critical for their valorisation. “Such datasets are also important in providing the evidence required by regulatory agencies to approve their use as animal feed,” he says. “This info also provides the confidence that producers and their nutritionists are required to incorporate such feedstuffs in their feeds.”

Looking forward, he adds that there are great opportunities in the use of enzyme technology and processing procedures to enhance nutritive value and minimise variability. “These technologies can be used to ‘uplift’ the nutritive value of ‘low- quality’ feedstuffs thus allowing them to contribute more to energy efficiency and nutrient supply in a diet,” he notes. “Also, by so doing, variability in terms of animal responses (e.g., variability in growth rates) is minimised because nutrients targets are met and potential negative impacts are mitigated.”

Join 26,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the feed sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht