Canada develops risk assessment model for feed mills

The Canadian Food Inspection Agency has developed a risk assessment model to evaluate the risk of each regulated feed mill in regard to their feed safety risks. This tool will support risk-informed oversight and the agency’s safeguarding mission.

The Canadian Food Inspection Agency (CFIA) is a science-based regulatory agency dedicated to safeguarding food, animals, and plants, thereby enhancing the health and well-being of the Canadian people, environment, and economy. In recent years, risks to food safety and the health of our animal and plant resources have changed considerably, alongside the rapid evolution of global trade patterns, innovation and new technologies. Therefore, the CFIA needs to adapt to be more efficient in protecting Canada’s resources while also supporting its industry’s ability to compete globally. In this context, the agency began developing a systematic risk-informed approach to better manage and prioritise its inspection resources and activities along the food supply continuum. This initiative prompted a streamlined approach to assess the health risks related to activities conducted in Canadian establishments under the CFIA’s jurisdiction: the Establishment-based Risk Assessment (ERA) models. From 2013-2016, the CFIA developed ERA models to quantify the food safety risk associated with products derived from domestic food establishments and hatcheries. This initiative was further extended in 2018 by introducing the development of the ERA model for livestock feed mills (ERA-Feed Mill model) to evaluate these establishments based on the level of risk they represent for the health of food animals in Canada (e.g. mycotoxins, drug carry-over). It also considers the risk to consumers that could derive from these animals (such as milk, meat, egg) (e.g. Salmonella spp., dioxins, prions). This is the first time that such a model considers both human and animal hazards in the evaluation of risk.

Development of the ERA-Feed Mill model

Selection of feed safety risk factors

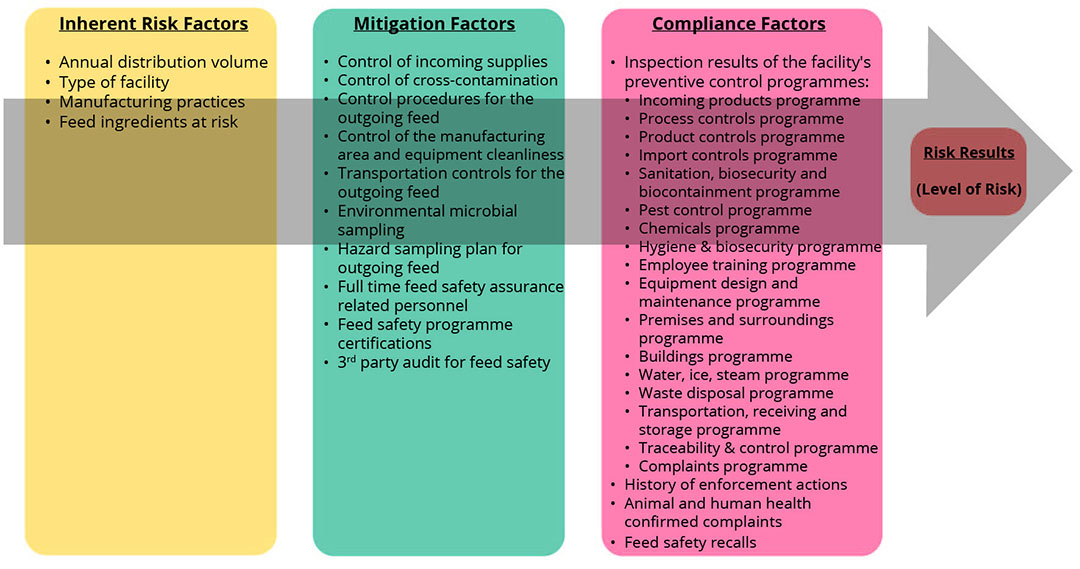

The first step in developing the risk assessment model was to select animal health and food safety-related risk factors (i.e. feed safety risk factors), pertaining to Canadian feed mill practices. This work involved a review of the scientific literature followed by consultations with a panel of 11 Canadian feed experts from academia, industry and the CFIA (see section Food Control). As a result, a final list of 34 risk factors and their assessment criteria was selected and grouped into 3 clusters:

- inherent risk factors,

- mitigation factors and

- compliance factors (Figure 1).

Inherent risk factors are related to specific types of operations or manufacturing processes in a feed mill, while mitigation factors are comprised of measures or strategies used by a feed mill to reduce the risk of occurrence of a feed safety issue, thereby reducing its inherent risk. Finally, compliance factors relate to a feed mill’s inspection track record with respect to how it complied with Canadian regulatory requirements. The selection of risk factors was conducted considering the proposed modernisation of Canada’s Feeds Regulations.

Figure 1 – ERA-Feed Mill arrow illustrating the risk factor clusters (inherent, mitigation and compliance and their respective risk factors.

Design of the model algorithm

In November 2019, 28 Canadian feed experts from academia, industry and government joined CFIA officials in a 2-round expert elicitation to estimate the relative importance of each criterion included in the model regarding feed safety risks. Based on experts’ opinion, criteria having the highest impact on risk increase were the use of prohibited materials combined with the production of ruminant feed (prohibited materials refer to most proteins derived from mammals that are banned from feeding to ruminants, in accordance with the Government of Canada’s Health of Animals Regulations Sections 162 to 164) and non-compliances related to the feed mill’s process and end-product control programmes. Risk mitigation criteria having the highest impact on decreasing the risk were, on the other side, the presence of feed safety certifications and the use of dedicated manufacturing lines (e.g. for prohibited materials or medicated feed). Results of this exercise were used to build the mathematical algorithm of the model. A peer-reviewed scientific paper on this study is available in the Journal of Food Protection.

Testing of the model outputs

From October 2019 to December 2020, the CFIA collected information from 62 randomly selected Canadian feed mills operated by livestock producers or commercial businesses. Data collected were used to provide first outputs of the ERA-Feed Mill model. Thereon, in July 2021, a performance assessment exercise was completed to estimate the agreement between the ERA-Feed Mill model outputs and the risk level assigned by 26 CFIA senior inspectors. The goals of this exercise were to test the applicability of the model and to refine it based on the identification of major discrepancies between the model and experts, if any. Preliminary results of this study show a good correlation between the model outputs and inspector/expert assessment. Once the analysis is finalised, results will be part of another scientific publication in a peer-reviewed journal.

How the ERA-Feed Mill model works

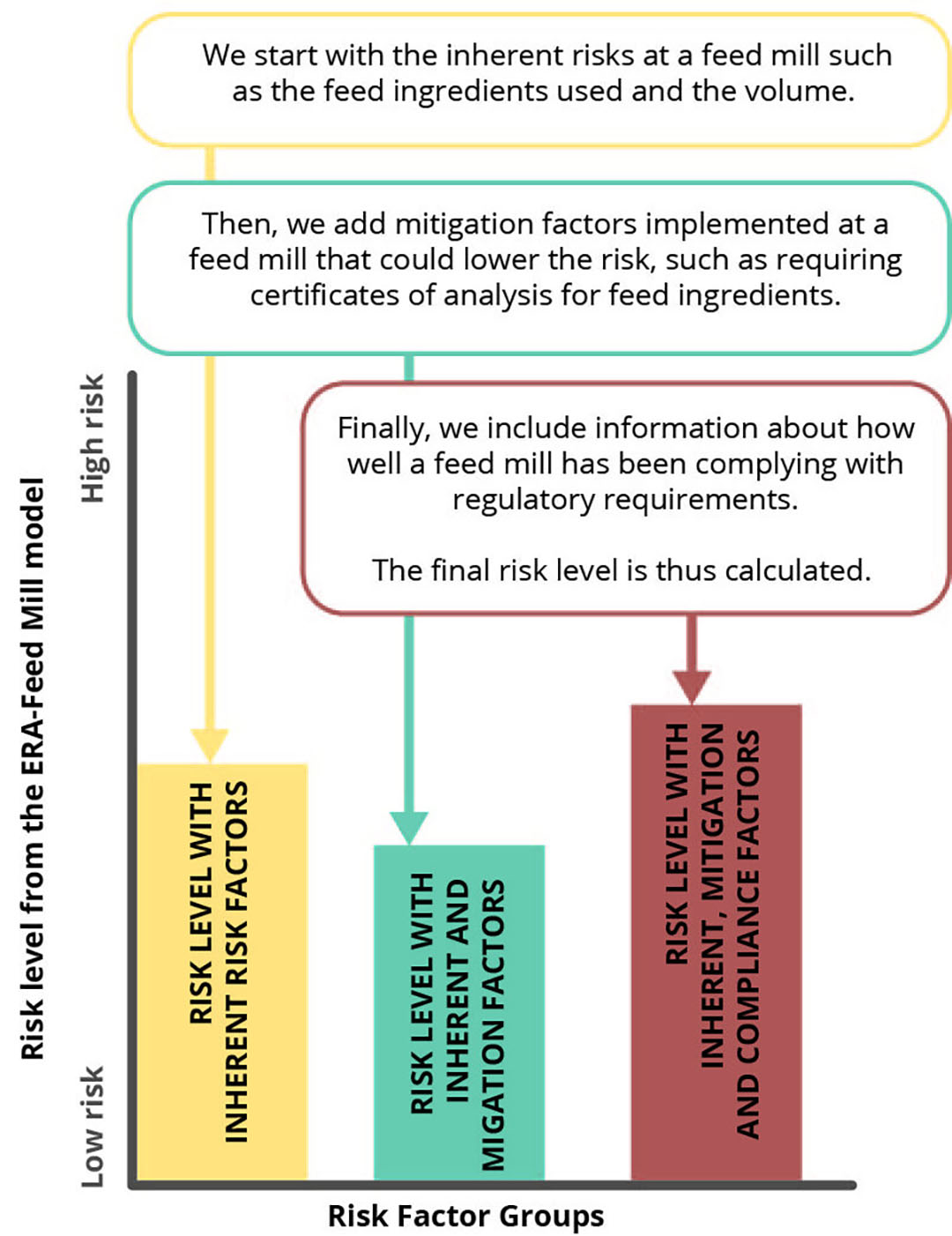

The ERA-Feed Mill model evaluates a feed mill based on three different clusters of risk factors (inherent, mitigation, and compliance) to determine its level of risk (Figure 2). The level of risk (final risk result) is calculated by considering the volume of feed distributed and the relative risk assigned to assessment criteria applicable to each feed mill. Information on the first 2 clusters is collected through a questionnaire provided to regulated parties whereas the information for the last cluster is extracted from inspection data. The final risk result will support priority setting, work planning, programme design, resource allocation and oversight activities. Higher risk feed mills requiring more attention will thus be easily identified and focused on.

Figure 2- How the ERA-Feed Mill model assigns a feed safety risk level.

Consistent and transparent approach

The CFIA’s ERA-Feed Mill model will provide a standardised, consistent and transparent approach to deliver timely results supporting risk-informed decision making in the Canadian regulated feed sector. Moreover, in 2019, the agency started working on the development of an ERA model applicable to inedible rendering plants, which is following the same scientific methodology as the ERA-Feed Mill model.

Several benefits are added to the use of the ERA-Feed Mill model such as the recognition of efforts made by the industry to mitigate their risk and to comply with regulatory requirements, a flexible approach which will adapt to changing trends in feed safety and within the feed industry, and an overall contribution to a greater consumer confidence in the safety of Canada’s feed and food products.

For additional information on all of the CFIA’s ERA models, please visit: www.inspection.canada.ca