Coated calcium chloride reduces hypocalcemia

Smart investment in the close-up cow period has shown the highest returns to dairy producers during 305 days of lactation cycle. Making diets more acidogenic with palatable coated calcium chloride facilitates easy calving with less metabolic disorders, resulting in better cow health, peak milk yield and lactation persistency.

Sound animal health is the corner stone of profitable animal agriculture. It is estimated that economic losses due to sub optimum animal health i.e. subclinical hypocalcemia (SCH) affects a much higher percentage of cows in the herd compared to clinical incidence of milk fever (Table 1).

Subclinical hypocalcemia affects beyond milk fever

In year 2012 and 2014, Martinez and co-workers studied the impact of subclinical hypocalcemia beyond milk fever. They concluded that SCH significantly (P<0.01) reduces dry matter intake, rumen contractions, neutrophil functions and increases the risk of metritis (p><0.05) in cows.>

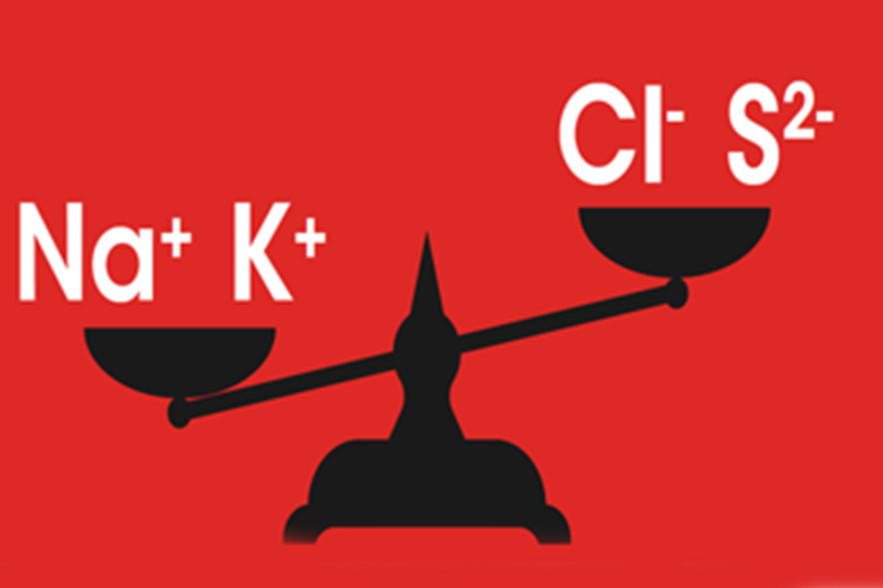

Making the diet acidogenic with the use of salts like calcium chloride, ammonium chloride (commonly referred to as anionic salts) etc. help in mobilising calcium from bones and thus maintain the blood calcium level during critical transition phase in dairy cows. It is a well proven concept, established through research trials conducted by several research institutes, globally.

Limitation of anionic Salts

Anionic salts are bitter in taste; hence they can have an impact on feed refusal. The degree of feed refusal varies from one salt to another. A 4 x 4 Latin Square Design trial was conducted at Schothorst Feed Research, the Netherlands, to determine the palatability measured as feed intake of TMR with 3 different anionic salts compared to control TMR.

4 groups of 12 animals were used in this study. Anionic salts were mixed with TMR. The dose was based on an identical dietary cation-anion balance (DCAB) concentration for all treatments. The dose of the test products followed practical application as for dry cows (Dose: -2,100 mEq/cow/day, 12 kg DM/cow/day = -175 mEq/kg DM).

In this research, it was found that 2.8% DMI in CaCl2 group, 5% DMI in Ammonium Chloride group and 0.6% DMI in NutriCAB group was decreased compared to the control group, see Figure 1. Higher reduction of dry matter during the prepartum phase in uncoated anionic salts could be very risky. Anionic salts are hygroscopic in nature. They can take up water and become clumps. They may lead to potential skin and eye irritations. In addition, handling and storage of these anionic salts is not easy. An encapsulated form of calcium chloride (NutriCAB) can address the concern related to uncoated anionic salts.

Coated calcium chloride reduces metabolic disorders

A NutriCAB trial was conducted in northern Italy in the month of December. The dry cows received 120g NutriCAB/head/day, starting from 21 days before calving. Metabolic disorders were recorded after calving.

The administration of coated calcium chloride in pre-parturient cows’ diet significantly reduced (p<0.05) metabolic disorders, see>Figure 2. The coated form of calcium chloride possesses free-flowing nature which makes it easy to manage during handling, storage and application at farm and factory level.

Economics of using coated calcium chloride

Considering the above example with a 2,000 cow herd, the saving on only subclinical hypocalcemia i.e. € 48,750 with an investment of € 20,000 (€ 10/cow/close up period) can provide a ROI of 1:2.4.

The average dose of coated calcium chloride is 130g/cow/day. However, customised dosages per farm are possible in consultation with a nutrition expert or veterinarian. Kemin also has a DCAB calculator available for use.

References available on request.