4 Best practices to get raw materials ready for processing

A virtuous cycle including strategies to preserve raw materials, detect contamination, introduce effective treatments and continuously monitor quality helps support safety across the feed-to-food chain.

Global grain production needs to almost double in the next 30 years to feed the world’s population. With hundreds of millions of Mt grain wasted annually, preserving existing resources is not an option, but a responsibility.

According to the latest estimates, nearly 30% of harvest yields are lost each year. Losses can occur during storage or via mycotoxin contamination in the field. Safeguarding grains and other raw materials against physical as well as nutritional losses caused by microbes is essential to providing safe animal feed.

Quality and safety of raw materials

Today’s market conditions are presenting challenges for stakeholders across the supply chain. Raw material price hikes, as well as shortages and supply disruptions in various regions, make it vital to keep raw material quality as constant as possible, for as long as possible. Multiple factors can allow microbes to multiply and proliferate, degrading the quality and safety of raw materials used in animal feed.

Factors such as weather or birds’ access to crops and grains, are beyond our control. When corn is planted, mould and mycotoxins in the soil may adversely affect the crops even before harvest. Left untreated, moulds can degrade nutritional value, while at the same time increasing moisture and temperatures, which favourable conditions for microbes such as Salmonella to proliferate. But the good news is, controllable countermeasures can help protect raw materials from feed safety threats.

The following 4 best practices can help ensure that raw materials are safe and ‘game ready’ for processing:

![]() Preserve early: It is important to preserve grains before they go into storage. Effective preservation strategies safeguard the quality of raw materials, allowing them to be stored at a higher moisture level and for a longer period of time. Trouw Nutrition research has shown that a synergistic blend of organic acids along with innovative technology allow raw materials to maintain their moisture content and free water (aW) value, while decreasing the mould counts (Figure 1).

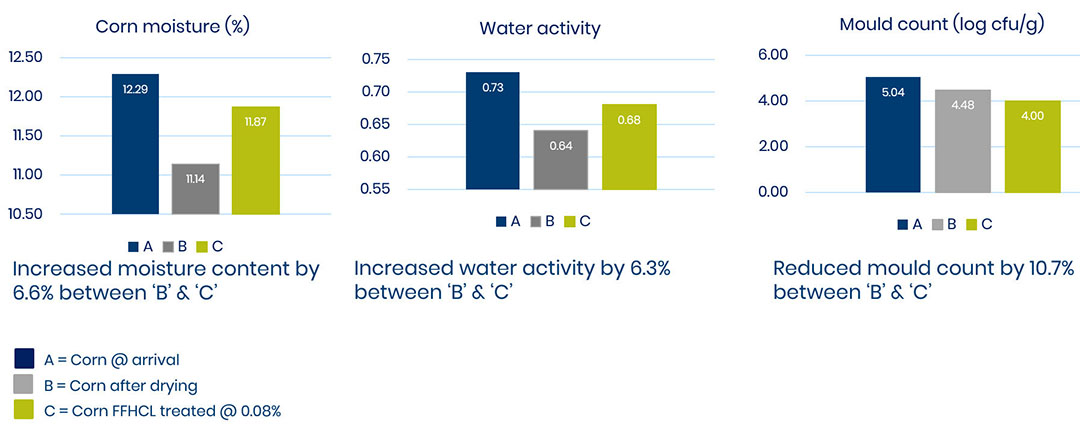

Preserve early: It is important to preserve grains before they go into storage. Effective preservation strategies safeguard the quality of raw materials, allowing them to be stored at a higher moisture level and for a longer period of time. Trouw Nutrition research has shown that a synergistic blend of organic acids along with innovative technology allow raw materials to maintain their moisture content and free water (aW) value, while decreasing the mould counts (Figure 1).

Figure 1 – Effect of raw material treatment on moisture, water activity and mould count.

![]() Early detection supports safety: Raw material quality is a prerequisite to feed safety and helps assure the highest possible nutritional value is delivered to animals in finished feed. Quality standards are on the minds of regulatory bodies around the globe. Harmful enterobacteriaceae, and specifically gram-negative pathogens like Salmonella, are in the spotlight when it comes to feed and food safety regulations.

Early detection supports safety: Raw material quality is a prerequisite to feed safety and helps assure the highest possible nutritional value is delivered to animals in finished feed. Quality standards are on the minds of regulatory bodies around the globe. Harmful enterobacteriaceae, and specifically gram-negative pathogens like Salmonella, are in the spotlight when it comes to feed and food safety regulations.

A good example of regulatory prudence comes from the European Union (EU). Materials such as oilseed protein meals exported from tropical climate countries to the European Union must comply with strict regulations and test negative for Salmonella presence. Early detection of feed safety risks can support economics, particularly for exports to the EU, where legislation does not allow for any raw materials or feed ingredients testing positive for Salmonella to be sold. To prevent contaminated raw materials from entering the EU, samples of a shipment are taken at time of a vessel’s departure and analysed for enterobacteriaceae. In the case of a positive Salmonella result, contaminated batches can be effectively treated upon arrival at the destination port.

Early detection and collaboration further mitigates risk. Managing Salmonella threats helps support optimal animal performance and protects food. Trouw Nutrition supports raw material producers, traders and processors to continually monitor and measure safety risks and provides guidelines to mitigate those risks from further affecting the feed production process.

Technologies that analyse raw materials and detect concerns at the point of harvest allow issues to be addressed early, reducing or even preventing contamination and re-contamination further down the chain.

![]() Effective treatment and application: Trouw Nutrition developed a strong solution to help mitigate harmful microbes. A combination of potent mixtures of buffered and non-buffered blends of organic acids and surfactants, along with dedicated dosing equipment allows for optimal dispersion and application. This approach delivers a holistic solution for treating raw materials testing positive for Salmonella. As potent products help preserve materials, buffering allows active ingredients to remain inside the material particles where they deliver a prolonged effect to help prevent (re-)contamination further down the chain (Figure 2).

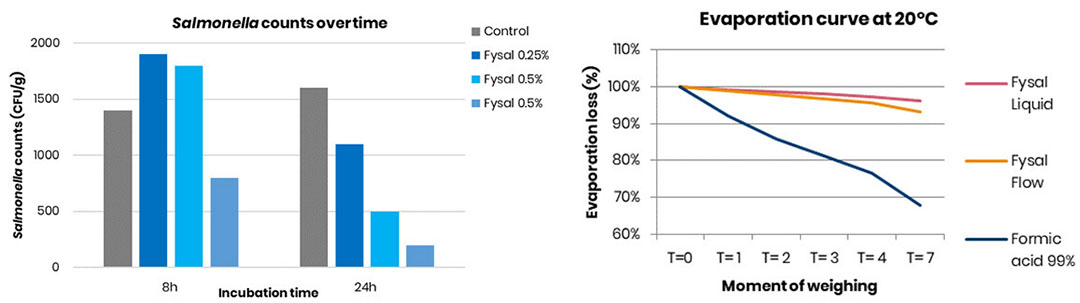

Effective treatment and application: Trouw Nutrition developed a strong solution to help mitigate harmful microbes. A combination of potent mixtures of buffered and non-buffered blends of organic acids and surfactants, along with dedicated dosing equipment allows for optimal dispersion and application. This approach delivers a holistic solution for treating raw materials testing positive for Salmonella. As potent products help preserve materials, buffering allows active ingredients to remain inside the material particles where they deliver a prolonged effect to help prevent (re-)contamination further down the chain (Figure 2).

Figure 2 – Effect of Fysal inclusion on Salmonella counts and effect of buffering on active ingredient availability.

![]() Continuous measurement and monitoring: Feed safety is an ongoing journey. Continuous measurement and monitoring of raw material quality from field to the farm is essential. Raw material traders and processors strive to ensure the best environment to minimise physical losses and safeguard the essential nutrients in raw materials. At Trouw Nutrition, our experts help feed industry professionals assure the best quality feed for animals, ultimately helping safeguard food for the consumers.

Continuous measurement and monitoring: Feed safety is an ongoing journey. Continuous measurement and monitoring of raw material quality from field to the farm is essential. Raw material traders and processors strive to ensure the best environment to minimise physical losses and safeguard the essential nutrients in raw materials. At Trouw Nutrition, our experts help feed industry professionals assure the best quality feed for animals, ultimately helping safeguard food for the consumers.

Collectively, these 4 best practices are helping the global animal feed industry manage safe feed production and operational excellence, helping feed the future.